Composting machinery

Composting machinery plays a crucial role in the efficient and effective processing of organic waste materials into nutrient-rich compost. With a wide range of machinery available, it is essential to understand the different types and their applications.

Compost Turners:

Compost turners are machines designed to aerate and mix the compost pile, promoting decomposition and preventing the formation of anaerobic conditions. They come in different configurations, including tractor-mounted, self-propelled, and tow-behind models. Compost turners effectively blend and fluff the compost, improving oxygen flow, temperature control, and microbial activity. They are commonly used in large-scale composting operations, such as municipal composting facilities and commercial composting sites.

Compost Shredders:

Compost shredders, also known as chipper shredders or compost grinders, are utilized to break down organic waste materials into smaller fragments. These machines accelerate the decomposition process by increasing the surface area of the materials, promoting faster breakdown and composting. Compost shredders are beneficial for reducing the volume of bulky waste materials, achieving uniform particle sizes, and creating a well-mixed compost pile. They are commonly used in both small-scale and large-scale composting operations.

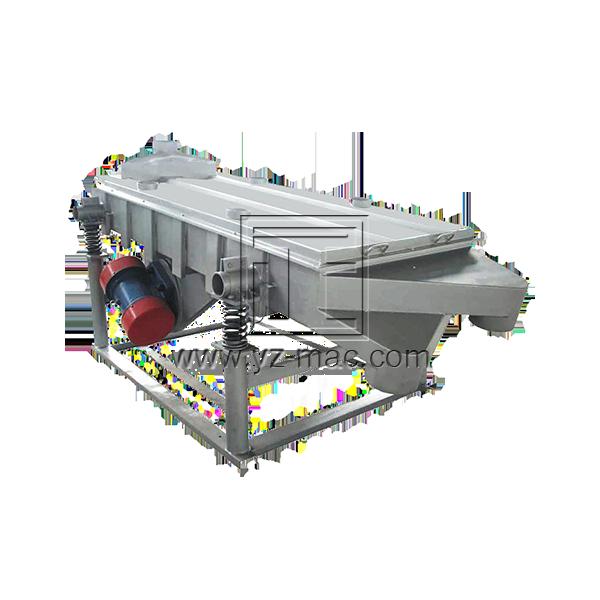

Compost Screeners:

Compost screeners, also referred to as trommel screens or vibrating screens, are used to separate larger particles, debris, and contaminants from the finished compost. These machines ensure a refined compost product with a consistent particle size, removing oversized materials and improving the compost’s quality and usability. Compost screeners are essential for applications such as agriculture, landscaping, and potting mixes, where a consistent texture and particle size are crucial.

Compost Bagging Machines:

Compost bagging machines are designed to automate the packaging of compost into bags or other containers. These machines streamline the packaging process, improving efficiency and reducing labor requirements. Compost bagging machines are commonly used in commercial composting facilities and retail operations, enabling convenient packaging and distribution of compost products to customers.

Compost Windrow Turners:

Compost windrow turners are specialized machines used to turn and aerate large compost windrows or piles. These machines effectively mix and oxygenate the compost, promoting the breakdown of organic materials and maintaining optimal conditions for composting. Compost windrow turners are suitable for medium to large-scale composting operations and are commonly used in agricultural settings, landscaping, and municipal composting facilities.

In-vessel Composting Systems:

In-vessel composting systems involve the use of enclosed containers or reactors to control the composting process. These systems offer precise temperature and moisture control, reducing odor emissions and promoting faster decomposition. In-vessel composting machinery includes rotating drums, agitated reactors, or static piles within controlled environments. These systems are commonly used in industrial-scale composting operations, food processing plants, and waste management facilities.

Applications of Composting Machinery:

Municipal composting facilities

Commercial composting operations

Agricultural composting and crop residue management

Landscaping and green waste management

Food processing and waste management facilities

Garden centers and nurseries

Organic farming and soil improvement projects

Conclusion:

Composting machinery encompasses a diverse range of equipment designed to enhance the composting process. From compost turners and shredders to screeners, bagging machines, and in-vessel systems, each type of machinery plays a unique role in achieving efficient and high-quality compost production. Understanding the different types of composting machinery and their applications allows for informed decision-making when selecting the appropriate equipment for specific composting needs. By utilizing the right composting machinery, we can optimize organic waste management, promote sustainable practices, and contribute to a healthier environment.