The complete and diverse disk granulation production line process is one of the main advantages of Henan Zheng Heavy Industries. We have experience in the planning and service of various fertilizer production lines. We not only focus on every process link in the production process, but also always grasp the details of each process on the whole production line and successfully achieve interlinking. We provide complete and reliable production line solutions according to the actual needs of customers.

The disc granulator production line is mainly used to produce compound fertilizer. Generally speaking, compound fertilizer contains at least two or three nutrients (nitrogen, phosphorus, potassium). It has the characteristics of high nutrient content and few side effects. Composite fertilizer plays an important role in balanced fertilization. It can not only improve the fertilization efficiency, but also promote the stable and high yield of crops. The production line of disk granulator is a good solution to achieve high-quality and high productivity of compound fertilizer. The production line can produce NPK fertilizer, DAP fertilizer and other compound fertilizer particles.

The raw materials for the production of compound fertilizers are urea, ammonium chloride, ammonium sulfate, liquid ammonia, ammonium monophosphate, diammonium phosphate, potassium chloride, potassium sulfate, including some clay and other fillers.

1) Nitrogen fertilizers: ammonium chloride, ammonium sulfate, ammonium thio, urea, calcium nitrate, etc.

2) Potassium fertilizers: potassium sulfate, grass and ash, etc.

3) Phosphorus fertilizers: calcium perphosphate, heavy calcium perphosphate, calcium magnesium and phosphate fertilizer, phosphate ore powder, etc.

The production line of disk granulator is advanced, efficient and practical, the equipment structure is compact, the automation is high, the operation is simple, and it is convenient for batch production of compound fertilizer.

1. All equipment is made of corrosion-resistant and wear-resistant materials.

2. Production capacity can be adjusted according to customer requirements.

3. No three waste emissions, energy saving and environmental protection. It runs steadily and is easy to maintain.

4. The compound fertilizer production line can not only produce high, medium and low concentration compound fertilizer, but also produce organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc. The granulation rate is high.

5. The layout of the whole production line is compact, scientific and reasonable, and the technology is advanced.

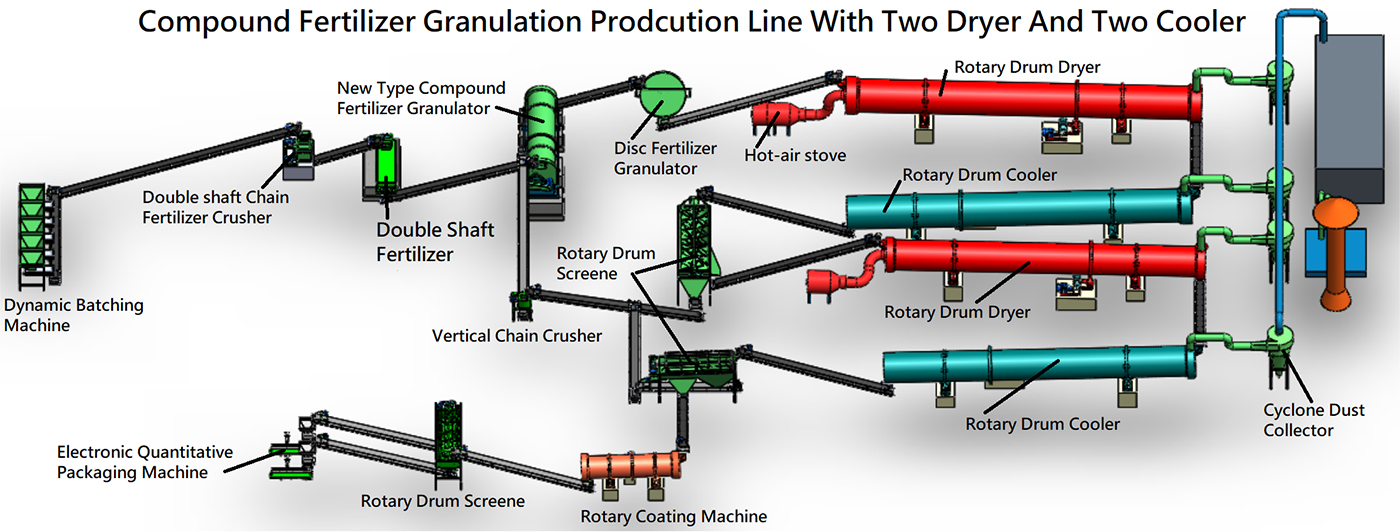

The production line equipment of the disk granulator includes ingredients warehouse → mixer (mixation) → disk granulator (granulator) → drum sieve machine (disting between substandard products and finished products) → vertical chain crusher (breaking) → automatic packaging machine (packaging) → belt conveyor (connection of various processes) and other equipment.Note: this production line is for reference only.

The process flow of disk granulator production line can usually be divided into:

1. Raw material ingredients process

First of all, distribute raw materials strictly in proportion. Raw materials include urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (ammonium phosphate, diammonium phosphate, calcium monophosphate, calcium carbonate), potassium chloride, potassium sulfate, etc. Strict raw material ratio can ensure high fertilizer efficiency.

2. Raw material mixing process

All raw materials are mixed and stirred evenly in the blender.

3. Broken process

The vertical chain crusher crushes large pieces of material into small pieces that can meet the granulation requirements. Then the belt conveyor sends the material into the disk granulation machine.

4. Granulation process

The disk angle of the disk granulation machine adopts an arc structure, and the ball forming rate can reach more than 93%. After the material enters the granulation plate, through the continuous rotation of the granulation disk and the spray device, the material is evenly bonded together to produce particles with a uniform shape and beautiful shape. Disk granulator is an indispensable equipment on the production line of compound fertilizer.

5. Screening process

The cooled material is transported to the roller sieve machine for screening. Qualified products can enter the finished warehouse through a belt conveyor, and can also be directly packaged. Unqualified particles will return to regrainate.

6. Packaging process

Packaging is the last process of compound fertilizer production line. The finished product is packaged with a fully automatic quantitative packaging machine. The high degree of automation and high efficiency not only achieve accurate weighing, but also excellently complete the final process. Users can control the feed speed and set the speed parameters according to actual requirements.