Organic fertilizer is a fertilizer made from livestock and poultry manure animal and plant waste by high temperature fermentation, which is very effective for soil improvement and fertilizer absorption. Organic fertilizers can be made of methane residue, agricultural waste, livestock and poultry manure and municipal waste. These organic waste needs to be further processed before they are converted into commercial organic fertilizers of commercial value for sale.

The investment in converting waste into wealth is absolutely worthwhile.

Organic fertilizer production lines are generally divided into pretreatment and granulation.

The main equipment in the pretreatment stage is the flip machine. At present, there are three main dumpers: grooved dumper, walking dumper and hydraulic dumper. They have different characteristics and can be selected according to actual needs.

In terms of granulation technology, we have a variety of granulators, such as rotary drum granulators, special granulators for new organic fertilizers, disk granulators, double helix extrusion granulators, etc. They can meet the demand for high-yielding and environmentally friendly organic fertilizer production.

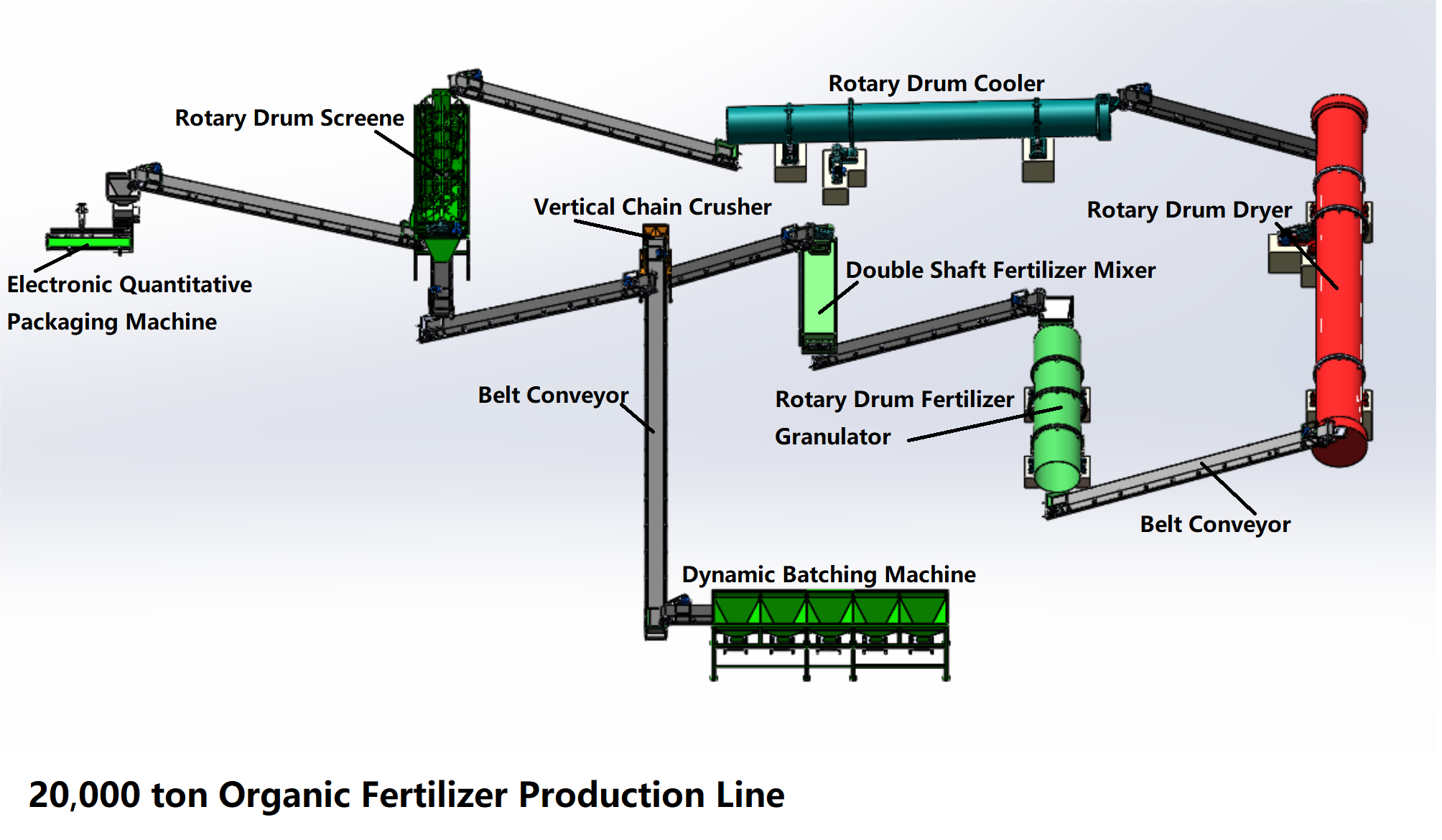

We aim to provide customers with a better and more environmentally friendly production line, which can assemble organic fertilizer production lines with 20,000 tons, 30,000 tons, or 50,000 tons or more production capacity according to actual production demand.

1. Animal excrement: chicken, pig's dung, sheep dung, cattle singing, horse manure, rabbit manure, etc.

2. Industrial waste: grapes, vinegar slag, cassava residue, sugar residue, biogas waste, fur residue, etc.

3. Agricultural waste: crop straw, soybean flour, cottonseed powder, etc.

4. Domestic waste: kitchen garbage

5. Sludge: urban sludge, river sludge, filter sludge, etc.

Organic fertilizer production line mainly consists of dumper, crusher, mixer, granulation machine, dryer, cooling machine, screening machine, wrapper, automatic packaging machine and other equipment.

- ►Obvious environmental benefits

Organic fertilizer production line with an annual output of 20,000 tons, taking livestock excrement as an example, the annual excrement treatment volume can reach 80,000 cubic meters.

- ►Realizable resource recovery

Take livestock and poultry manure as an example, a pig's annual excrement combined with other excipients can produce 2,000 to 2,500 kilograms of high-quality organic fertilizer, which contains 11% to 12% organic matter (0.45% nitrogen, 0.19% phosphorus pentaoxide, 0.6% potassium chloride, etc.), which can satisfy an acre. Fertilizer demand for field materials throughout the year.

Organic fertilizer particles produced in the organic fertilizer production line are rich in nitrogen, phosphorus, potassium and other nutrients, with a content of more than 6%. Its organic matter content is more than 35%, which is higher than the national standard.

- ►Considerable economic benefits

Organic fertilizer production lines are widely used in farmland, fruit trees, garden greening, high-end lawns, soil improvement and other fields, which can meet the demand for organic fertilizer in local and surrounding markets, and produce good economic benefits.

1. Fermentation

Fermentation of biological organic raw materials plays a very important role in the whole production process of organic fertilizer. Full fermentation is the basis for the production of high-quality organic fertilizer. The above-mentioned dumpers have their own advantages. Both grooved and groove hydraulic dumpers can achieve complete fermentation of composting, and can achieve high stacking and fermentation, with great production capacity. Walking dumper and hydraulic flip machine are suitable for all kinds of organic raw materials, which can operate freely inside and outside the factory, greatly improving the speed of aerobic fermentation.

2. Smash

Semi-wet material crusher produced by our factory is a new type of high-efficiency single crusher, which is highly adaptable to organic materials with high water content. Semi-humid material crusher is widely used in organic fertilizer production, which has a good crushing effect on wet raw materials such as chicken manure and sludge. The grinder greatly shortens the production cycle of organic fertilizer and saves production costs.

3. Stir

After the raw material is crushed, mixed with other auxiliary materials and stirred evenly to make granulation. Double-axis horizontal mixer is mainly used for pre-hydration and mixing of powdered materials. The spiral blade has multiple angles. Regardless of the shape, size and density of the blade, the raw materials can be mixed quickly and evenly.

4. Granulation

Granulation process is the core part of organic fertilizer production line. The new organic fertilizer granulator achieves high-quality uniform granulation through continuous stirring, collision, mosaic, sphericalization, granulation and dense process, and its organic purity can be as high as 100%.

5. Dry and cool

The roller dryer continuously pumps the heat source in the hot air stove at the nose position to the tail of the engine through the fan installed at the tail of the machine, so that the material is in full contact with the hot air and reduce the water content of the particles.

The roller cooler cools particles at a certain temperature after drying. While reducing the particle temperature, the water content of the particles can be reduced again, and about 3% of the water can be removed through the cooling process.

6. Sieve

After cooling, there are still powdery substances in the finished particulate products. All powders and unqualified particles can be screened through a roller sieve. Then, it is transported from the belt conveyor to the blender and stirred to make granulation. Unqualified large particles need to be crushed before granulation. The finished product is transported to the organic fertilizer coating machine.

7. Packaging

This is the last production process. The fully automatic quantitative packaging machine produced by our company is an automatic packaging machine specially designed and manufactured for particles of different shapes. Its weighing control system meets the requirements of dustproof and waterproof, and can also configure the material box according to customer requirements. Suitable for bulk packaging of bulk materials, it can automatically weigh, convey and seal bags.