Powdered organic fertilizer is usually used to improve the soil and provide nutrients for crop growth. They can also be quickly decomposed when they enter the soil, releasing nutrients quickly. Because powdery solid organic fertilizer is absorbed at a slower rate, powdered organic fertilizers are stored longer than liquid organic fertilizers. The use of organic fertilizer has greatly reduced the damage to the plant itself and the soil environment.

Organic fertilizer provides organic matter to the soil, thus providing plants with the nutrients they need to help build healthy soil systems, rather than destroying them. Organic fertilizer therefore contains huge business opportunities. With the gradual restrictions and prohibition of fertilizer use in most countries and relevant departments, the production of organic fertilizer will become a huge business opportunity.

Any organic raw material can be fermented into organic compost. In fact, compost is crushed and screened to become a high-quality marketable powdery organic fertilizer.

1. Animal excrement: chicken, pig's dung, sheep dung, cattle singing, horse manure, rabbit manure, etc.

2, industrial waste: grapes, vinegar slag, cassava residue, sugar residue, biogas waste, fur residue, etc.

3. Agricultural waste: crop straw, soybean flour, cottonseed powder, etc.

4. Household garbage: kitchen waste.

5, sludge: urban sludge, river sludge, filter sludge, etc.

The process needed to produce powdered organic fertilizers such as neem bread powder, cocoa peat powder, oyster shell powder, dried beef dung powder, etc. includes fully composting raw materials, crushing the resulting compost, and then screening and packaging them.

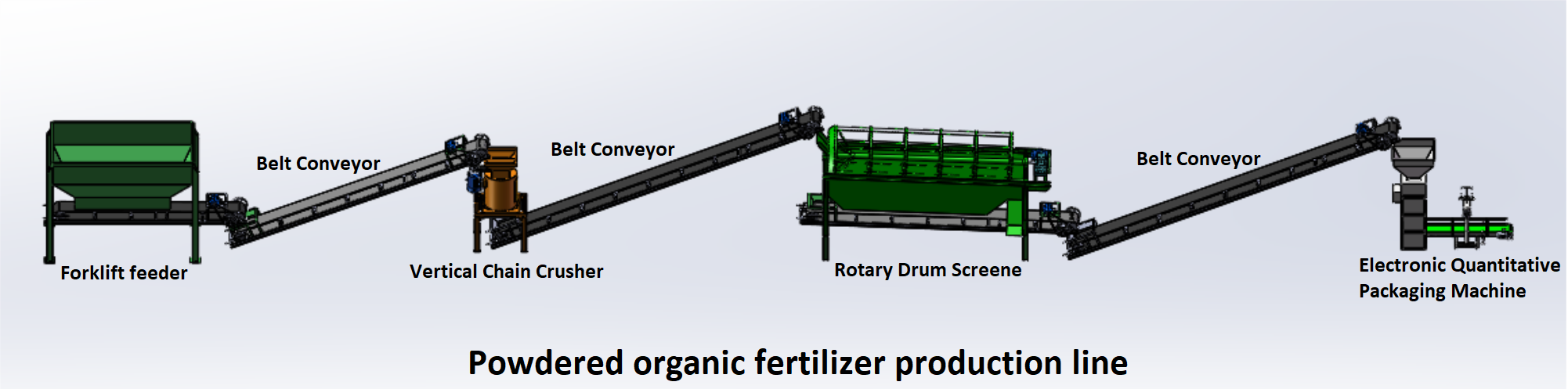

Powdered organic fertilizer production line has simple technology, small cost of investment equipment, and simple operation.

We provide professional technical service support, planning according to customer needs, design drawings, on-site construction suggestions, etc.

Powdered organic fertilizer production process: compost - crushing - sieve - packaging.

1. Compost

Organic raw materials are regularly carried out through the dumper. There are several parameters that affect compost, namely particle size, carbon-nitrogen ratio, water content, oxygen content and temperature. Attention should be paid to:

1. Crush the material into small particles;

2. The carbon-nitrogen ratio of 25-30:1 is the best condition for effective composting. The more types of incoming materials, the greater the chance of effective decomposition is to maintain the appropriate C:N ratio;

3. The optimal moisture content of compost raw materials is generally about 50% to 60%, and Ph is controlled at 5.0-8.5;

4. The roll-up will release the heat of the compost pile. When the material decomposes effectively, the temperature decreases slightly with the overturning process, and then returns to the previous level within two or three hours. This is one of the powerful advantages of the dumper.

2. Smash

A vertical strip grinder is used to crush compost. By crushing or grinding, blocky substances in compost can be decomposed to prevent problems in packaging and affect the quality of organic fertilizer.

3. Sieve

The roller sieve machine not only removes impurities, but also selects unqualified products, and transports compost to the sieve machine through a belt conveyor. This process process is suitable for drum sieve machines with medium size sieve holes. Sieving is indispensable for the storage, sale and application of compost. Sieving improves the structure of compost, improves the quality of compost, and is more beneficial to subsequent packaging and transportation.

4. Packaging

The sieved fertilizer will be transported to the packaging machine to commercialize powdery organic fertilizer that can be directly sold through weighing, usually with 25 kg per bag or 50 kg per bag as a single packaging volume.