High Quality Fertilizer Granulator

A high-quality fertilizer granulator is a vital machine in the production of granular fertilizers. It plays a significant role in improving nutrient efficiency, enhancing crop yields, and promoting sustainable agriculture.

Benefits of a High-Quality Fertilizer Granulator:

Efficient Nutrient Delivery: A high-quality fertilizer granulator converts raw materials into granules, ensuring controlled nutrient release. Granular fertilizers provide a consistent and reliable nutrient supply to plants, optimizing nutrient uptake and reducing the risk of nutrient loss through leaching or volatilization.

Enhanced Crop Yields: Granular fertilizers produced by a high-quality granulator provide balanced and targeted nutrient application, leading to improved crop yields. The controlled-release of nutrients supports the plant’s growth stages, ensuring proper nutrition throughout the growing season.

Reduced Nutrient Loss: Granular fertilizers minimize nutrient loss compared to traditional powdered or liquid fertilizers. The granules are less prone to runoff, minimizing environmental pollution and maximizing nutrient utilization by crops.

Ease of Handling and Application: Granular fertilizers are easy to handle and apply, allowing for uniform distribution and precise dosage. The granules can be accurately spread using mechanical applicators, ensuring even coverage and minimizing fertilizer wastage.

Working Principle of a High-Quality Fertilizer Granulator:

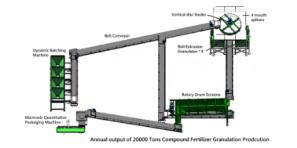

A high-quality fertilizer granulator operates based on different principles, including extrusion, rolling, or tumbling. These machines typically consist of a granulating chamber, a rotating drum or plate, and an agglomeration system. The raw materials, such as nitrogen, phosphorus, potassium, and other additives, are mixed and fed into the granulating chamber. The rotating drum or plate facilitates the formation of granules by agglomerating the materials through pressure, heat, or binding agents. The resulting granules are then dried and cooled for storage or further processing.

Applications of High-Quality Fertilizer Granulators:

Agricultural Crop Production: High-quality fertilizer granulators are widely used in agricultural crop production to manufacture granular fertilizers. These granules provide precise nutrient delivery, ensuring optimal crop growth and maximizing yield potential.

Horticulture and Greenhouse Cultivation: Fertilizer granulators are valuable tools in horticulture and greenhouse cultivation. Granular fertilizers offer controlled nutrient release, supporting the growth of flowers, fruits, and vegetables, and maintaining optimal nutrient levels in controlled environments.

Organic Fertilizer Production: High-quality granulators are essential in the production of organic fertilizers. They help convert organic materials, such as compost, animal manure, and crop residues, into granules, enhancing nutrient availability and improving soil health in organic farming systems.

Soil Remediation and Land Reclamation: Fertilizer granulators have applications in soil remediation and land reclamation projects. They facilitate the production of granular amendments for improving soil structure, nutrient content, and fertility in degraded or contaminated soils.

A high-quality fertilizer granulator is a valuable machine for the production of granular fertilizers, offering numerous benefits in nutrient efficiency, crop yield improvement, and sustainable agriculture. By utilizing granular fertilizers produced by these granulators, farmers and growers can optimize nutrient delivery, minimize nutrient loss, and enhance crop productivity. Whether in agricultural crop production, horticulture, organic farming, or soil remediation, high-quality fertilizer granulators contribute to efficient nutrient management and promote environmentally responsible fertilizer use.