Fertilizer production equipment

Fertilizer production equipment is used to produce various types of fertilizers, including organic and inorganic fertilizers, which are essential for agriculture and horticulture. The equipment can be used to process a variety of raw materials, including animal manure, crop residues, and chemical compounds, to create fertilizers with specific nutrient profiles.

Some common types of fertilizer production equipment include:

1.Composting equipment: Used to turn organic waste materials into compost, which can be used as a natural fertilizer.

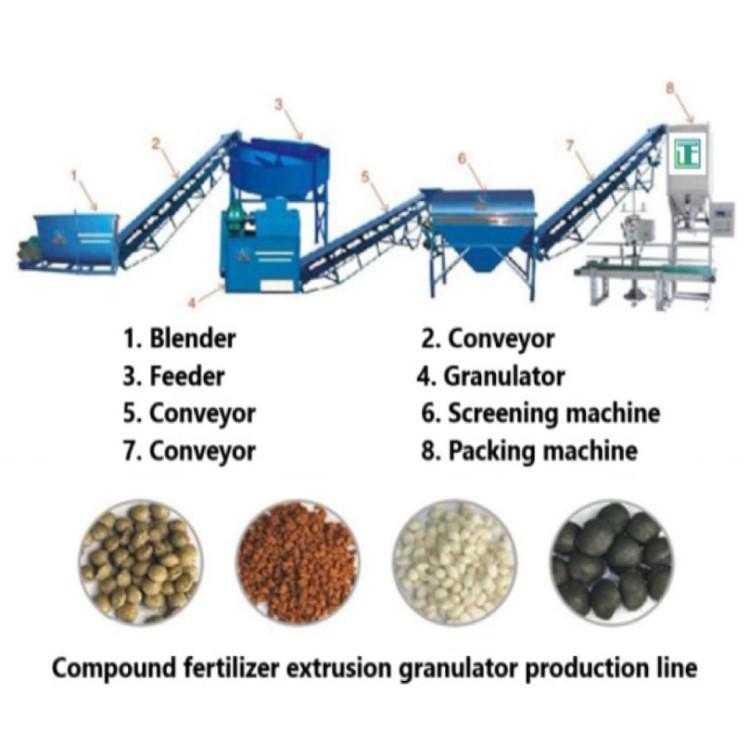

2.Mixing and blending equipment: Used to combine different ingredients and create a homogeneous mixture, such as mixing raw materials to create a fertilizer blend.

3.Granulating equipment: Used to convert powders or fine particles into larger, more uniform granules or pellets, which are easier to handle, transport and store.

4.Drying and cooling equipment: Used to remove moisture from the fertilizer and reduce its temperature to prevent degradation and ensure a longer shelf life.

5.Bagging and packaging equipment: Used to automatically weigh, fill, and seal bags of fertilizer for transport and storage.

6.Screening and grading equipment: Used to remove any impurities or oversized particles from the fertilizer before packaging and distribution.

Fertilizer production equipment is available in a range of sizes and capacities to suit different applications and production needs. The choice of equipment depends on the specific requirements of the fertilizer being produced, including the nutrient profile, production capacity, and budget.