Commercial composting systems

Commercial composting systems are comprehensive and integrated setups designed for large-scale composting operations in commercial or industrial settings. These systems consist of various components and processes that work together to efficiently and effectively convert organic waste into high-quality compost.

Waste Collection and Sorting:

Commercial composting systems typically involve the collection and sorting of organic waste materials. This may include food waste, yard waste, agricultural residues, and other biodegradable materials. The system provides designated containers or areas for the collection and separation of different types of organic waste.

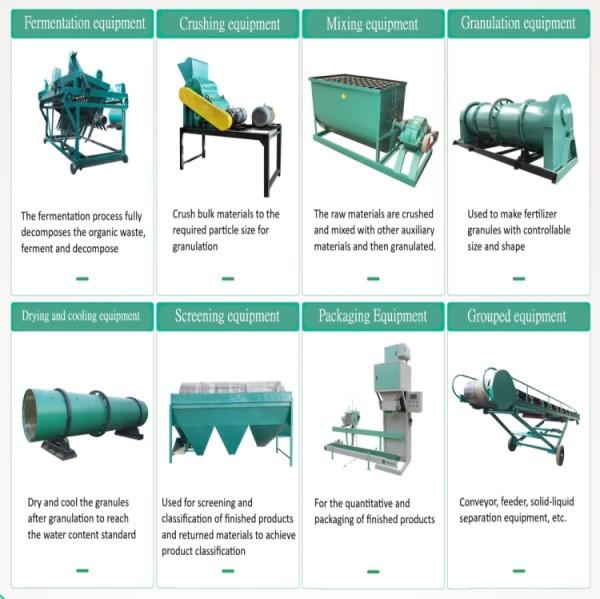

Pre-processing and Shredding:

In some commercial composting systems, the organic waste materials undergo pre-processing and shredding. This step helps break down the waste into smaller pieces, increasing the surface area for microbial activity and accelerating the decomposition process. Pre-processing can involve grinding, shredding, or chopping the waste materials to optimize their suitability for composting.

Composting Piles or Vessels:

Commercial composting systems employ large composting piles or vessels to contain and manage the organic waste during the composting process. These piles or vessels provide a controlled environment for microbial decomposition, ensuring proper aeration, moisture levels, and temperature regulation. They can be open windrows, in-vessel composting systems, or other specialized setups depending on the specific system design.

Aeration and Moisture Management:

Commercial composting systems incorporate mechanisms for efficient aeration and moisture management. Proper airflow and oxygen supply are essential for the activity of aerobic microorganisms involved in decomposition. Moisture levels need to be monitored and adjusted to maintain the ideal conditions for microbial activity and prevent the compost from becoming too dry or waterlogged.

Temperature Monitoring and Control:

Temperature monitoring and control systems are vital components of commercial composting systems. Monitoring the internal temperature of the compost piles or vessels helps assess the progress of decomposition and ensures that the composting process reaches and maintains the desired temperature range. Temperature control can be achieved through proper insulation, turning the compost, or utilizing specialized heat-generating systems.

Turning and Mixing:

Commercial composting systems often incorporate turning and mixing mechanisms to ensure thorough mixing of the composting materials. Regular turning or mixing helps redistribute moisture, enhance aeration, and promote uniform decomposition. This process prevents the formation of anaerobic zones, optimizes microbial activity, and reduces the risk of odor issues.

Odor Control and Emission Management:

Odor control is a critical aspect of commercial composting systems. To minimize odors, these systems employ technologies such as biofilters, activated carbon filters, or other odor mitigation methods. Emission management strategies may include proper venting, off-gas treatment, or capturing and treating any odorous gases generated during the composting process.

Maturation and Screening:

Once the composting process is complete, commercial composting systems facilitate the maturation and screening of the compost. Maturation involves allowing the compost to stabilize and further decompose over a period, resulting in a mature and ready-to-use product. Screening processes help remove any remaining impurities, such as oversized materials or contaminants, producing a refined and high-quality compost product.

Quality Assurance and Testing:

Commercial composting systems often incorporate quality assurance measures, including testing the compost for nutrient content, pH levels, and maturity. These tests help ensure that the final compost product meets specific quality standards and regulatory requirements.

Environmental Benefits and Sustainability:

Commercial composting systems contribute to waste reduction, resource conservation, and environmental sustainability. By diverting organic waste from landfills, these systems help reduce greenhouse gas emissions, prevent soil and water pollution, and promote a circular economy by transforming waste into a valuable resource.

In conclusion, commercial composting systems offer efficient and integrated solutions for large-scale composting operations. They encompass various processes, including waste collection, pre-processing, composting piles or vessels, aeration, moisture management, temperature control, turning, odor control, maturation, screening, quality assurance, and environmental sustainability.