Organic fertilizer granulation production line

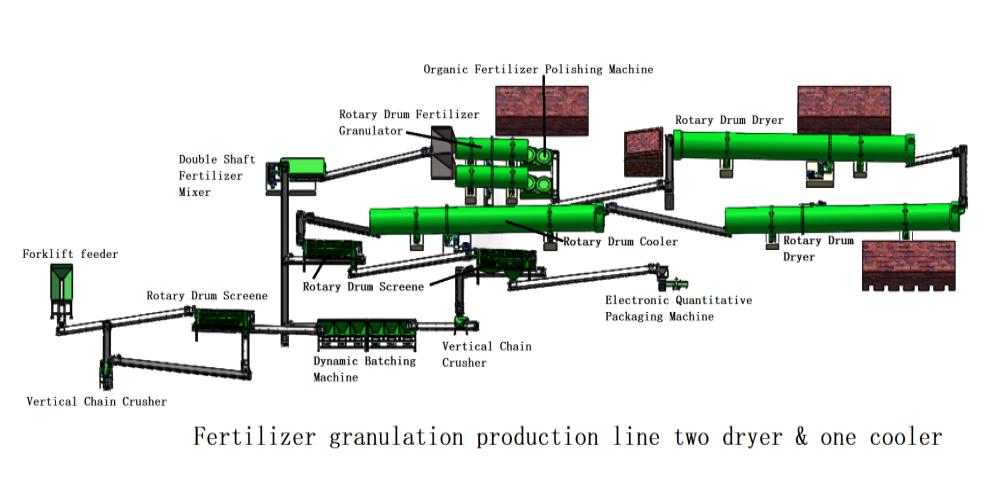

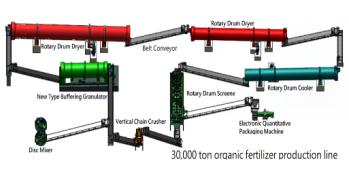

An organic fertilizer granulation production line is a set of equipment used to convert organic waste materials into granular fertilizer products. The production line typically includes a series of machines such as compost turner, crusher, mixer, granulator, dryer, cooler, screening machine, and packing machine.

The process starts with the collection of organic waste materials, which may include animal manure, crop residue, food waste, and sewage sludge. The waste is then turned into compost through the process of composting, which involves the use of a compost turner to ensure proper aeration and mixing of the organic matter.

After the composting process, the compost is crushed and mixed with other ingredients such as nitrogen, phosphorus, and potassium to create a balanced fertilizer mixture. The mixture is then fed into a granulator machine, which converts the mixture into granular fertilizer through a process called extrusion.

The extruded granules are then dried to reduce the moisture content and to ensure they are stable for storage. The dried granules are cooled and screened to remove any oversized or undersized particles, and finally, the finished products are packed into bags or containers for distribution and sale.

Overall, an organic fertilizer granulation production line is a highly efficient and environmentally friendly way of converting organic waste materials into valuable fertilizer products that can be used to improve soil fertility and plant growth.