Compost crusher

A compost crusher, also known as a compost shredder or grinder, is a specialized machine designed to break down and reduce the size of organic waste materials during the composting process. It plays a crucial role in preparing the composting materials by creating a more uniform and manageable particle size, facilitating decomposition and accelerating the production of high-quality compost.

Size Reduction:

A compost crusher is designed to break down organic waste materials into smaller particles. It employs blades, hammers, or other crushing mechanisms to effectively reduce the size of the composting materials. By breaking down the organic matter into smaller pieces, the crusher creates a larger surface area for microbial activity, accelerating the decomposition process.

Improved Decomposition:

The smaller particle size achieved through compost crushing enhances the contact between microorganisms and organic matter. This improves the availability of nutrients and promotes efficient decomposition. The increased surface area and improved accessibility of organic matter lead to faster breakdown and more thorough composting.

Homogeneous Compost Mixture:

A compost crusher ensures a more uniform and consistent mixture of composting materials. It helps eliminate potential clumps or uneven distribution of materials, ensuring that the composting process is consistent throughout the pile or container. A homogeneous compost mixture promotes uniform decomposition and reduces the risk of incomplete or partially decomposed pockets.

Enhanced Oxygenation and Aeration:

The crushing action of a compost crusher helps improve oxygenation and aeration within the composting materials. It breaks up compacted or densely packed material, allowing for better airflow and facilitating the growth of aerobic microorganisms. Proper oxygenation and aeration contribute to a well-balanced composting process and minimize the risk of anaerobic conditions and associated odor issues.

Increased Surface Area for Microbial Activity:

The smaller particle size resulting from compost crushing provides a larger surface area for microbial colonization and activity. This allows microorganisms to more efficiently break down the organic matter and convert it into compost. The increased microbial activity leads to faster decomposition and improved compost quality.

Reduction of Bulky Waste:

Compost crushers are particularly useful for processing bulky organic waste materials, such as branches, tree trimmings, crop residues, or yard waste. By reducing the size of these materials, the crusher facilitates their incorporation into the composting process. This improves the overall efficiency of waste management and compost production.

Time and Labor Savings:

Using a compost crusher saves time and labor compared to manual or traditional methods of breaking down organic waste. The machine automates the crushing process, allowing for efficient and consistent particle size reduction without the need for manual labor. This increases productivity and reduces labor costs, making compost production more efficient and cost-effective.

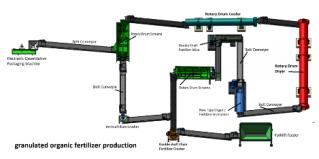

Integration with Composting Systems:

Compost crushers can be integrated into existing composting systems or used as standalone units. They can be combined with other composting equipment, such as mixers, turners, or screening machines, to create a comprehensive composting system. The integration of a crusher enhances the overall efficiency and effectiveness of the composting process.

In conclusion, a compost crusher is a valuable machine for reducing the size of organic waste materials during the composting process. It improves decomposition, promotes uniformity, enhances oxygenation and aeration, increases surface area for microbial activity, reduces bulky waste, saves time and labor, and can be integrated into existing composting systems.