Fertilizer machine price

When considering investing in a fertilizer machine, understanding the price factors is crucial. The cost of a fertilizer machine depends on various factors, including its type, size, capacity, features, and brand reputation.

Type of Fertilizer Machine:

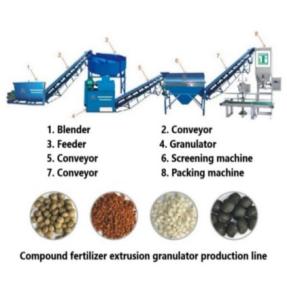

There are different types of fertilizer machines available, including granulators, mixers, dryers, composting equipment, and packaging machines. Each type serves a specific function in the fertilizer production process. The prices of these machines can vary based on their complexity, technology, and efficiency.

Machine Size and Capacity:

The size and capacity of the fertilizer machine also affect its price. Larger machines with higher production capacities are generally more expensive than smaller ones. Assess your specific production needs and consider the scale of your operation to determine the appropriate size and capacity required for your fertilizer production.

Manufacturing Materials and Quality:

The quality of materials used in the construction of the fertilizer machine can impact its price. Machines built with high-quality materials, such as stainless steel or corrosion-resistant alloys, tend to be more expensive but offer better durability and longevity. Ensure the machine is built to withstand the demands of fertilizer production.

Advanced Features and Technology:

Fertilizer machines equipped with advanced features and technology may come at a higher price point. These features could include automation capabilities, digital controls, precision dosing, energy efficiency, and remote monitoring. Assess whether these advanced features are essential for your production needs and consider the added value they bring to justify the price.

Brand Reputation and Support:

The reputation and reliability of the brand manufacturing the fertilizer machine can impact the price. Established and reputable brands often charge a premium for their machines due to their proven performance, quality assurance, and after-sales support. Consider the brand’s track record, customer reviews, and warranty terms when evaluating the price.

Additional Services and Support:

Some fertilizer machine suppliers may offer additional services, such as installation, training, maintenance, and technical support. These services may be included in the overall price or offered as separate packages. Assess the level of support provided by the supplier and consider its impact on the overall value of the machine.

The price of a fertilizer machine depends on several factors, including the machine type, size, capacity, materials, features, brand reputation, and additional services. Carefully evaluate these factors, keeping in mind your production requirements, budget constraints, and long-term goals. Prioritize quality, durability, and performance over cost alone to ensure a reliable and efficient fertilizer machine that meets your specific needs.