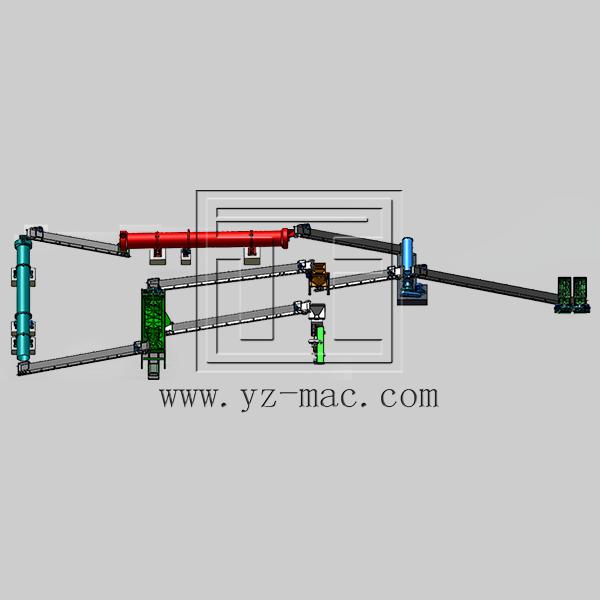

Graphite pellet extrusion system

A graphite pellet extrusion system is a specialized setup or equipment used for the extrusion of graphite pellets. It typically consists of various components and machinery that work together to form graphite pellets of a specific size and shape. Here are some key elements commonly found in a graphite pellet extrusion system:

1. Extruder: The extruder is the core component of the system. It includes a screw or ram mechanism that applies pressure to the graphite material, forcing it through a die or mold to shape it into pellets.

2. Die or Mold: The die or mold is a specially designed component that gives the extruded graphite its desired shape and dimensions. It determines the size, diameter, and sometimes the texture of the pellets.

3. Hopper: The hopper is a container where the graphite feedstock, usually in the form of powder or a mixture, is stored and fed into the extruder. It ensures a steady and controlled supply of material.

4. Heating and Cooling Systems: Some extrusion systems may incorporate heating and cooling mechanisms to control the temperature of the graphite material during the extrusion process. This helps optimize the extrusion process and ensure the desired properties of the pellets.

5. Control Panel: A control panel is used to monitor and adjust various parameters of the extrusion system, such as temperature, pressure, speed, and pellet size. It provides operators with control over the process and allows for precise adjustments.

6. Conveyor System: In larger-scale production setups, a conveyor system may be employed to transport the extruded graphite pellets to subsequent processing or packaging stages.

The graphite pellet extrusion system may also include additional components depending on specific requirements, such as material preparation equipment, pellet drying systems, and quality control mechanisms. https://www.yz-mac.com/roll-extrusion-compound-fertilizer-granulator-product/