Bio-organic fertilizer production line

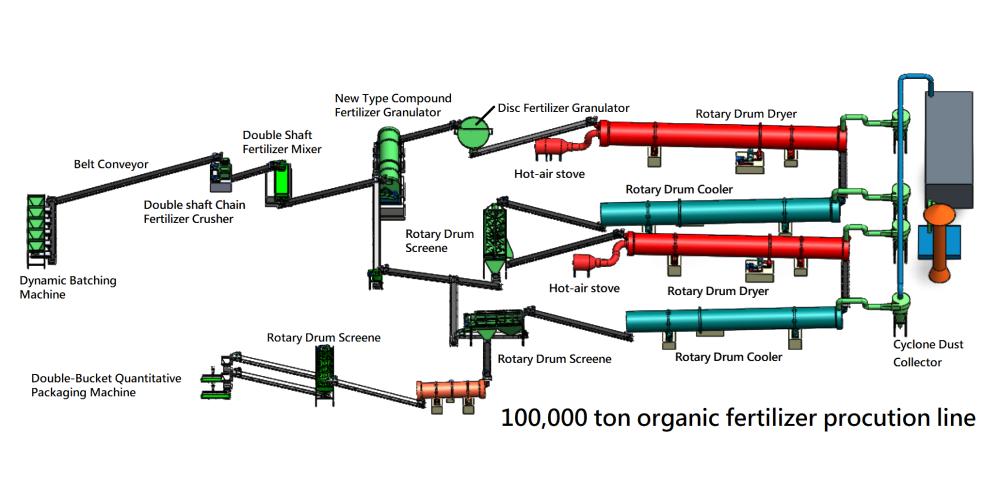

A bio-organic fertilizer production line typically involves the following processes:

1.Raw Material Handling: The first step is to collect and handle the raw materials, which may include animal manure, crop residues, kitchen waste, and other organic materials. The materials are sorted and processed to remove any large debris or impurities.

2.Fermentation: The organic materials are then processed through a fermentation process. This involves creating an environment that is conducive to the growth of microorganisms that break down the organic matter. The result is a nutrient-rich compost that is high in organic matter.

3.Crushing and Screening: The compost is then crushed and screened to ensure that it is uniform and to remove any unwanted materials.

4.Mixing: The crushed compost is then mixed with other organic materials, such as bone meal, blood meal, and other organic fertilizers, to create a balanced nutrient-rich blend.

5.Granulation: The mixture is then granulated using a granulation machine to form granules that are easy to handle and apply.

6.Drying: The newly formed granules are then dried to remove any moisture that may have been introduced during the granulation process.

7.Cooling: The dried granules are cooled to ensure that they are at a stable temperature before they are packaged.

8.Packaging: The final step is to package the granules into bags or other containers, ready for distribution and sale.

It is important to note that bio-organic fertilizers are made from organic materials and are rich in nutrients and beneficial microorganisms. They can help improve soil fertility, increase crop yields, and promote sustainable agriculture practices. To ensure that the final product is of high quality, it is important to implement appropriate sanitation and quality control measures throughout the production process.

Overall, a bio-organic fertilizer production line can help reduce waste, promote sustainable agriculture practices, and provide a high-quality and effective organic fertilizer for crops.