Organic fertilizer production process

The organic fertilizer production process generally involves the following steps:

1.Collection of organic materials: Organic materials such as animal manure, crop residues, food waste, and other organic wastes are collected and transported to the processing plant.

2.Pre-processing of organic materials: The collected organic materials are pre-processed to remove any contaminants or non-organic materials. This may involve shredding, grinding, or screening the materials.

3.Mixing and composting: The pre-processed organic materials are mixed together in a specific ratio to create a balanced blend of nutrients. The mixture is then placed in a composting area or composting machine, where it is kept at a specific temperature and moisture level to encourage the growth of beneficial microorganisms. The composting process typically takes several weeks to several months to complete, depending on the type of composting system used.

4.Crushing and screening: Once the composting process is complete, the organic material is crushed and screened to create a uniform particle size.

5.Granulation: The organic material is then fed into a granulation machine, which shapes the material into uniform granules or pellets. The granules may be coated with a layer of clay or other material to improve their durability and slow release of nutrients.

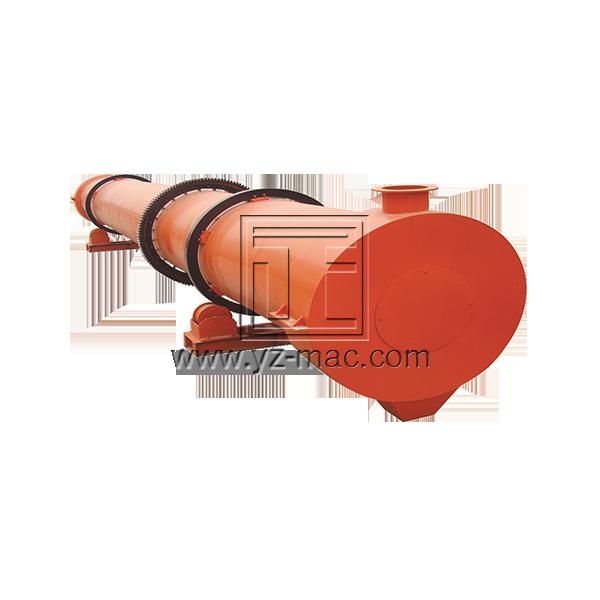

6.Drying and cooling: The granules are then dried and cooled to remove any excess moisture and improve their storage stability.

7.Packaging and storage: The final product is packaged in bags or other containers and stored until it is ready for use as fertilizer.

It’s important to note that the organic fertilizer production process can vary depending on the specific equipment and technology used by the manufacturer.