Organic fertilizer drying equipment

Organic fertilizer drying equipment refers to machines used for drying organic fertilizers after the fermentation process. This is an important step in the production of organic fertilizers because moisture content affects the quality and shelf life of the finished product.

Some examples of organic fertilizer drying equipment include:

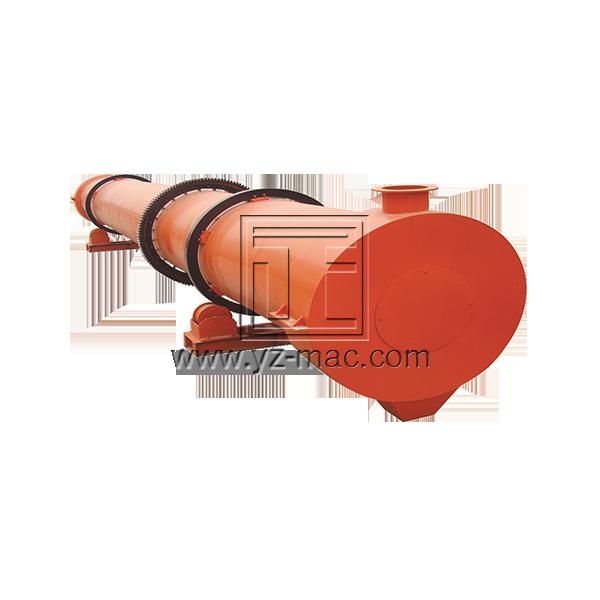

Rotary drum dryer: This machine uses hot air to dry organic fertilizers. The drum rotates, which helps to evenly distribute the fertilizer as it dries.

Belt dryer: This machine uses a conveyor belt to transport the fertilizer through a drying chamber, where hot air is blown over it.

Fluidized bed dryer: This machine suspends the fertilizer particles in a stream of hot air, allowing for more efficient drying.

Other equipment, such as fans and heaters, may be used in conjunction with these dryers to ensure that the fertilizer is dried thoroughly and evenly.