Organic fertilizer production line

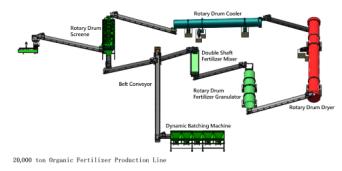

An organic fertilizer production line is a series of machines and equipment used to convert organic waste materials into high-quality organic fertilizers. The production line typically includes the following stages:

1.Pre-treatment: The raw materials such as animal manure, agricultural waste, and food waste are collected and sorted, and large materials are shredded or crushed to ensure they are of a uniform size.

2.Fermentation: The pre-treated materials are placed in a composting machine or a fermentation tank, where they are fermented for a certain period of time to produce organic compost.

3.Crushing and mixing: The fermented compost is then crushed and mixed with other organic materials such as bone meal, blood meal, and fish meal, to create a balanced and nutrient-rich fertilizer mixture.

4.Granulation: The mixed fertilizer is then passed through a granulator machine, which shapes the fertilizer mixture into small, round granules.

5.Drying and cooling: The granulated fertilizer is then dried and cooled to remove excess moisture and improve its shelf life.

6.Packaging: The final product is packaged in bags or containers for storage and distribution.

An organic fertilizer production line can be customized according to the specific requirements of the customer, such as production capacity and type of raw materials. It is important to choose high-quality machines and equipment from reliable manufacturers to ensure efficient and effective organic fertilizer production.