Organic Fertilizer Processing Equipment

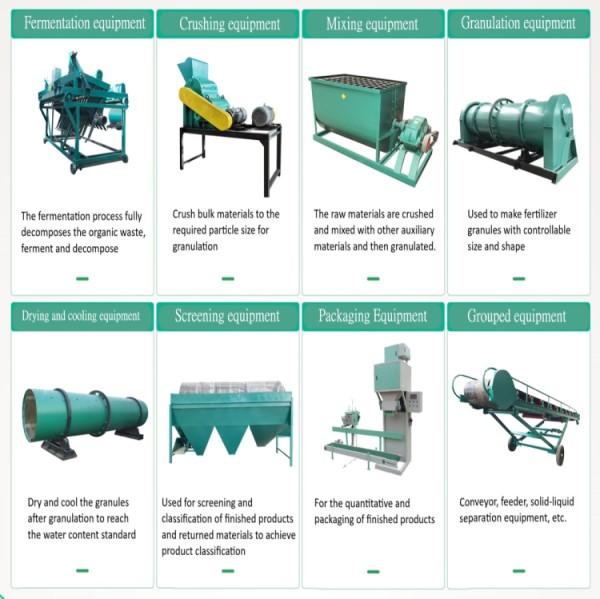

Organic fertilizer processing equipment is a range of machines and tools used in the production of organic fertilizers. The equipment can vary depending on the specific requirements of the production process, but some of the most common organic fertilizer processing equipment includes:

1.Composting equipment: This includes equipment such as compost turners, windrow turners, and compost bins that are used to facilitate the composting process.

2.Crushing and screening equipment: This includes crushers, shredders, and screeners that are used to crush and screen organic materials before they are mixed with other ingredients.

3.Mixing and blending equipment: This includes mixers, blenders, and agitators that are used to mix organic materials with other ingredients, such as minerals and micronutrients, to create a balanced and nutrient-rich fertilizer.

4.Granulation equipment: This includes granulators, pelletizers, and extruders that are used to turn the mixed fertilizer into pellets or granules for easier application.

5.Drying and cooling equipment: This includes dryers, coolers, and humidifiers that are used to dry and cool the granulated fertilizer to remove excess moisture and improve the shelf life of the product.

6.Packaging equipment: This includes bagging machines, conveyors, and labeling equipment that are used to package and label the final product for distribution.

Organic fertilizer processing equipment may vary in size, complexity, and cost depending on the specific needs and requirements of the organic fertilizer production process. It is important to choose high-quality equipment from reliable manufacturers to ensure efficient and effective organic fertilizer production.