Organic Fertilizer Processing Equipment

Organic fertilizer processing equipment refers to the machines and tools used in the production process of organic fertilizers. Some common types of organic fertilizer processing equipment include:

1.Fermentation equipment: used for the decomposition and fermentation of raw materials into organic fertilizers. Examples include compost turners, fermentation tanks, and in-vessel composting systems.

2.Crushing and grinding equipment: used to crush and grind raw materials into smaller particles. Examples include crusher machines, hammer mills, and grinding machines.

3.Mixing and blending equipment: used to mix and blend different raw materials to achieve the desired fertilizer formula. Examples include horizontal mixers, vertical mixers, and batch mixers.

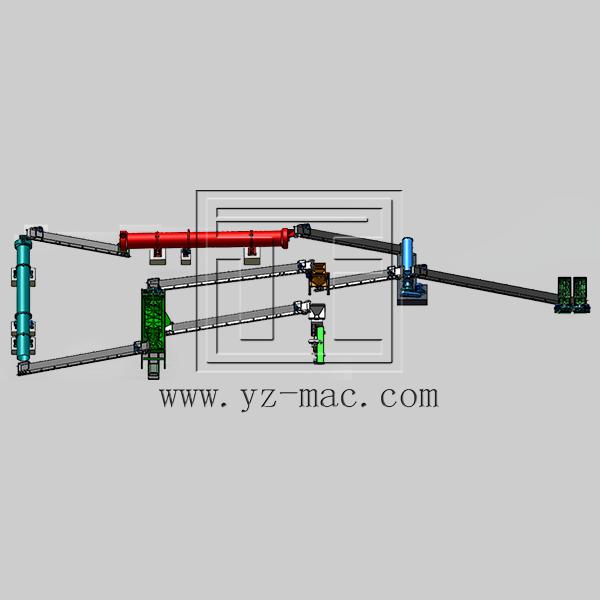

4.Granulating equipment: used to granulate the mixed and blended raw materials into finished organic fertilizers. Examples include rotary drum granulators, disc granulators, and double roller granulators.

5.Drying and cooling equipment: used to dry and cool the granulated organic fertilizers. Examples include rotary dryers, fluidized bed dryers, and cooling machines.

6.Screening and packing equipment: used to screen and pack the finished organic fertilizers. Examples include screening machines, vibrating screens, and packaging machines.

These are just some examples of the equipment used in organic fertilizer processing. The specific equipment used may vary depending on the type and scale of the organic fertilizer production process.