Organic fertilizer machinery

Organic fertilizer machinery plays a crucial role in the production of organic fertilizers, providing efficient and sustainable solutions for enhancing soil fertility and promoting healthy plant growth. These specialized machines enable the conversion of organic materials into nutrient-rich fertilizers through processes such as fermentation, composting, granulation, and drying.

Importance of Organic Fertilizer Machinery:

Sustainable Soil Health: Organic fertilizer machinery allows for the efficient utilization of organic waste materials, such as crop residues, animal manure, food waste, and green biomass. By transforming these materials into organic fertilizers, the machinery helps replenish the soil with essential nutrients, organic matter, and beneficial microorganisms. This promotes long-term soil health, improves soil structure, and enhances nutrient cycling.

Environmental Sustainability: Organic fertilizer machinery supports sustainable agricultural practices by reducing reliance on synthetic fertilizers and minimizing environmental pollution. By recycling organic waste and converting it into valuable fertilizers, these machines contribute to waste reduction, resource conservation, and the prevention of nutrient runoff into water bodies.

Nutrient-Rich Fertilizers: Organic fertilizer machinery facilitates the production of nutrient-rich fertilizers with a balanced composition of essential nutrients, including nitrogen (N), phosphorus (P), and potassium (K). These fertilizers provide a steady release of nutrients, promoting optimal plant growth, improving crop yields, and enhancing the nutritional value of agricultural produce.

Types of Organic Fertilizer Machinery:

Compost Turners: Compost turners are used to efficiently mix and aerate organic waste materials during the composting process. These machines facilitate the decomposition of organic matter, accelerating the breakdown of raw materials into nutrient-rich compost.

Fermentation Equipment: Fermentation equipment, such as fermentation tanks or bio-reactors, is employed in the anaerobic fermentation process. This process converts organic materials into biofertilizers or liquid fertilizers through microbial activity, ensuring the release of beneficial microorganisms and bioactive compounds.

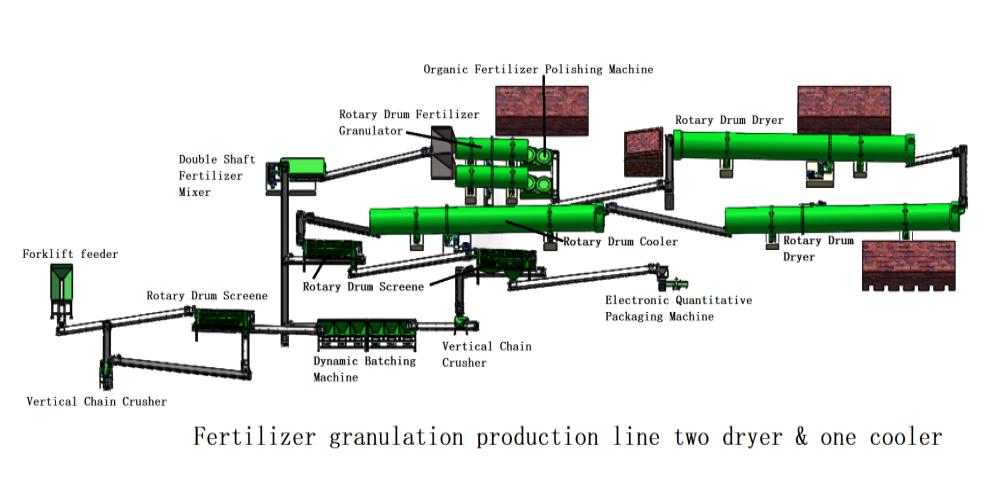

Granulation Machines: Granulation machines are utilized to convert organic materials into granular organic fertilizers. These machines agglomerate the raw materials into uniform granules, enhancing their storage stability, ease of application, and controlled nutrient release.

Drying Equipment: Drying equipment is employed to reduce the moisture content of organic fertilizers, improving their shelf life and preventing microbial growth. This equipment utilizes heat and airflow to remove excess moisture from the granulated or powdered fertilizers.

Applications of Organic Fertilizer Machinery:

Agriculture and Horticulture: Organic fertilizer machinery finds wide applications in agriculture and horticulture. These machines enable the production of high-quality organic fertilizers, which are essential for improving soil fertility, enhancing plant growth, and promoting sustainable farming practices.

Organic Farming: Organic farmers rely on organic fertilizer machinery to produce customized organic fertilizers that comply with organic farming standards. These fertilizers nourish the soil, support natural pest and disease control, and promote the overall health and productivity of organic crops.

Waste Management and Recycling: Organic fertilizer machinery plays a pivotal role in waste management and recycling initiatives. By converting organic waste materials into valuable fertilizers, these machines contribute to waste reduction, divert organic waste from landfills, and support the circular economy.

Land Rehabilitation: Organic fertilizer machinery assists in land rehabilitation projects, especially in degraded or contaminated soils. The application of organic fertilizers produced by these machines helps restore soil fertility, improve soil structure, and establish vegetation in areas affected by erosion, mining, or industrial activities.

Organic fertilizer machinery is essential for sustainable agriculture, waste management, and soil health improvement. These machines enable the conversion of organic waste materials into nutrient-rich fertilizers, contributing to long-term soil fertility, environmental sustainability, and enhanced crop productivity. With various types of machinery available, including compost turners, fermentation equipment, granulation machines, and drying equipment, organic fertilizer production can be tailored to specific requirements.