Organic fertilizer granules machine

An organic fertilizer granules machine, also known as an organic fertilizer granulator, is a specialized equipment designed to convert organic materials into uniform, round granules for efficient and convenient fertilizer application. This machine plays a crucial role in the organic fertilizer production process by improving the nutrient content, ease of handling, and effectiveness of organic fertilizers.

Benefits of an Organic Fertilizer Granules Machine:

Enhanced Nutrient Release: The granulation process through an organic fertilizer granules machine helps encapsulate and protect the nutrients present in organic materials. This leads to controlled and gradual nutrient release, allowing plants to access the required nutrients over an extended period, resulting in improved crop growth and productivity.

Improved Fertilizer Efficiency: Organic fertilizer granules are uniform in size, shape, and nutrient content. This uniformity ensures consistent nutrient distribution when applied to the soil, maximizing fertilizer efficiency and minimizing nutrient loss through leaching or volatilization. The targeted application of granules facilitates better nutrient absorption by plant roots.

Easy Handling and Application: Organic fertilizer granules are easy to handle, transport, and apply. Their uniform size and shape enable uniform spreading, reducing the risk of over or under application. Granules are less prone to dust generation, making them convenient to handle and reducing potential health hazards associated with fertilizer application.

Reduced Environmental Impact: Organic fertilizer granules minimize nutrient runoff and leaching into water bodies, reducing the risk of water pollution. The controlled release of nutrients reduces the need for frequent fertilizer applications, minimizing the environmental impact and ensuring sustainable nutrient management in agricultural systems.

Working Principle of an Organic Fertilizer Granules Machine:

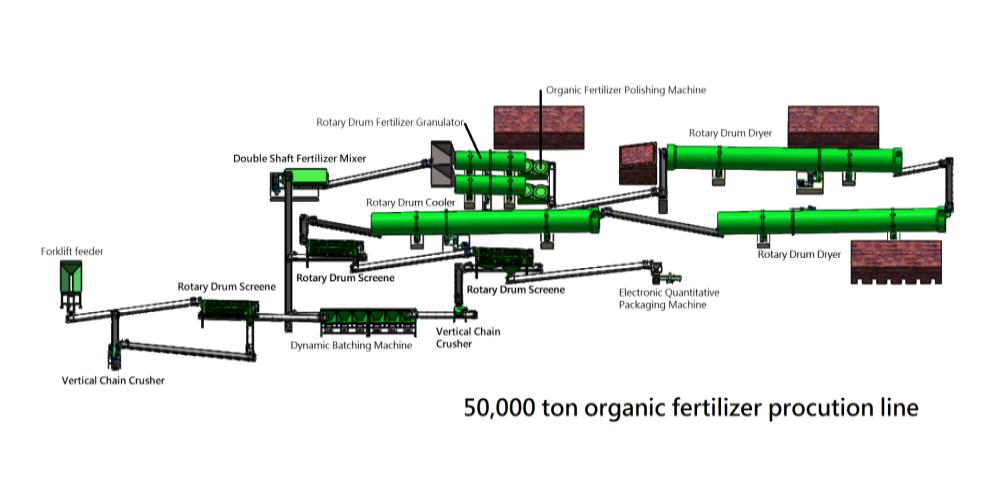

An organic fertilizer granules machine utilizes a combination of mechanical and chemical processes to convert organic materials into granules. The machine typically consists of a rotating drum or pan, where the organic material is introduced. As the drum or pan rotates, a liquid binder or adhesive is sprayed onto the material, causing the particles to adhere and form granules. The granules are then dried and cooled, ready for packaging and application.

Applications of Organic Fertilizer Granules:

Agriculture and Horticulture: Organic fertilizer granules are extensively used in conventional and organic farming systems to provide essential nutrients to crops, vegetables, fruits, and ornamental plants. The controlled release of nutrients ensures optimal plant growth, improves soil fertility, and promotes sustainable agriculture practices.

Soil Improvement and Restoration: Organic fertilizer granules are applied to degraded or nutrient-deficient soils to improve soil structure, enhance microbial activity, and replenish soil organic matter. This application helps restore soil health, increase nutrient availability, and support the growth of beneficial soil organisms.

Greenhouse and Nursery Production: Organic fertilizer granules are commonly used in greenhouse and nursery operations. They provide a consistent nutrient source to young plants, seedlings, and transplants, promoting healthy root development and vigorous growth. The slow-release nature of the granules ensures a continuous supply of nutrients throughout the growing season.

Landscaping and Turf Management: Organic fertilizer granules are beneficial in landscaping projects, such as lawns, gardens, parks, and sports fields. They deliver essential nutrients to the soil, promoting healthy grass growth, improving soil structure, and reducing the need for synthetic fertilizers.

An organic fertilizer granules machine plays a vital role in the production of high-quality organic fertilizers. By converting organic materials into uniform granules, this machine enhances nutrient release, fertilizer efficiency, ease of handling, and reduces environmental impact. Organic fertilizer granules find applications in agriculture, horticulture, soil improvement, greenhouse production, landscaping, and turf management.