Organic Fertilizer Dryer

Send email to us

Previous:

Organic Fertilizer Rotary Dryer

Next:

Organic fertilizer drying equipment

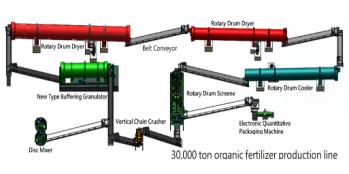

Organic fertilizer dryer is a machine that is used to dry organic fertilizer pellets or powder. The dryer uses a hot air stream to remove moisture from the fertilizer materials, reducing the moisture content to a level that is suitable for storage and transportation. Organic fertilizer dryer can be classified into different types based on the heating source, including electric heating, gas heating, and bioenergy heating. The machine is widely used in organic fertilizer production plants, compound fertilizer production plants, and other chemical and agricultural industries.

Write your message here and send it to us