NPK compound fertilizer production line

An NPK compound fertilizer production line is a comprehensive system designed to produce NPK fertilizers, which contain essential nutrients for plant growth: nitrogen (N), phosphorus (P), and potassium (K). This production line combines different processes to ensure the accurate blending and granulation of these nutrients, resulting in high-quality and balanced fertilizers.

The Significance of NPK Compound Fertilizers:

NPK compound fertilizers play a vital role in modern agriculture, as they provide a balanced combination of essential nutrients needed for plant growth. Nitrogen promotes leaf and stem development, phosphorus enhances root growth and flower/fruit formation, and potassium improves overall plant health, disease resistance, and stress tolerance. By providing a balanced nutrient supply, NPK compound fertilizers contribute to increased crop yield, improved quality, and sustainable agricultural practices.

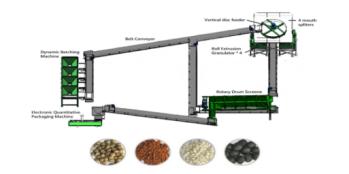

Components of an NPK Compound Fertilizer Production Line:

Raw Material Pre-treatment: Raw materials, such as urea, ammonium nitrate, phosphate rock, and potassium chloride, undergo pre-treatment processes like crushing, grinding, and drying to ensure uniform particle size and moisture content.

Mixing and Blending: The pre-treated raw materials are accurately weighed and mixed in the required proportions to achieve the desired NPK ratio. Mixing equipment ensures thorough blending, creating a homogenous mixture of nutrients.

Granulation: The blended materials are further processed through granulation, where the mixture is transformed into granules to facilitate easier application and nutrient release. Granulation techniques include drum granulation, extrusion granulation, and spray granulation.

Drying and Cooling: The granules are dried to remove excess moisture and cooled to prevent clumping. This step ensures the stability and longevity of the granular fertilizer.

Screening and Coating: The dried and cooled granules are sieved to remove undersized or oversized particles, ensuring consistent size distribution. Optional coating processes can be applied to enhance granule durability, slow-release properties, or add additional micronutrients.

Benefits of NPK Compound Fertilizers:

Balanced Nutrient Supply: NPK compound fertilizers provide a balanced combination of nitrogen, phosphorus, and potassium, ensuring that plants have access to all essential nutrients for healthy growth and optimal yield.

Increased Crop Productivity: The precise nutrient ratios in NPK compound fertilizers promote plant development, leading to increased crop productivity, improved quality, and higher market value for agricultural products.

Nutrient Efficiency and Reduced Environmental Impact: NPK compound fertilizers are formulated to release nutrients gradually, ensuring efficient uptake by plants and minimizing nutrient loss through leaching or volatilization. This reduces environmental pollution and improves nutrient-use efficiency.

Customizable Formulations: NPK compound fertilizers can be tailored to specific crop requirements and soil conditions, allowing farmers to address nutrient deficiencies and optimize plant nutrition for different crops and growth stages.

Simplified Fertilizer Management: The use of NPK compound fertilizers simplifies fertilizer management for farmers. With the balanced nutrient composition in a single product, farmers can ensure accurate and efficient nutrient application, reducing the complexity and cost associated with multiple fertilizer types.

An NPK compound fertilizer production line offers a comprehensive solution to produce high-quality fertilizers that supply essential nutrients for plant growth. The balanced combination of nitrogen, phosphorus, and potassium in NPK compound fertilizers contributes to increased crop productivity, improved quality, and sustainable agricultural practices. By implementing an NPK compound fertilizer production line, farmers can enhance nutrient management, optimize crop nutrition, and achieve higher yields while minimizing environmental impact.