Large scale vermicomposting systems

Large-scale composting plays a crucial role in sustainable waste management by diverting organic waste from landfills and transforming it into valuable compost. To achieve efficient and effective composting on a larger scale, specialized equipment is essential.

The Significance of Large-Scale Composting Equipment:

Large-scale composting equipment is designed to handle significant volumes of organic waste materials, making it suitable for municipal, commercial, and industrial composting operations. These equipment not only enhance the efficiency of the composting process but also contribute to environmental sustainability by reducing greenhouse gas emissions and conserving landfill space.

Types of Large-Scale Composting Equipment:

Compost Turners:

Compost turners are machines specifically designed to aerate and mix the compost piles. They facilitate the decomposition process by ensuring proper oxygen flow, temperature control, and homogenous mixing of organic materials. Compost turners come in various sizes and configurations to accommodate different composting volumes.

Compost Windrow Turners:

Compost windrow turners are large machines that are capable of turning and mixing long, horizontal compost windrows. They are ideal for large-scale composting operations where windrows are commonly used. These turners enhance aeration, optimize temperature distribution, and promote microbial activity throughout the windrow.

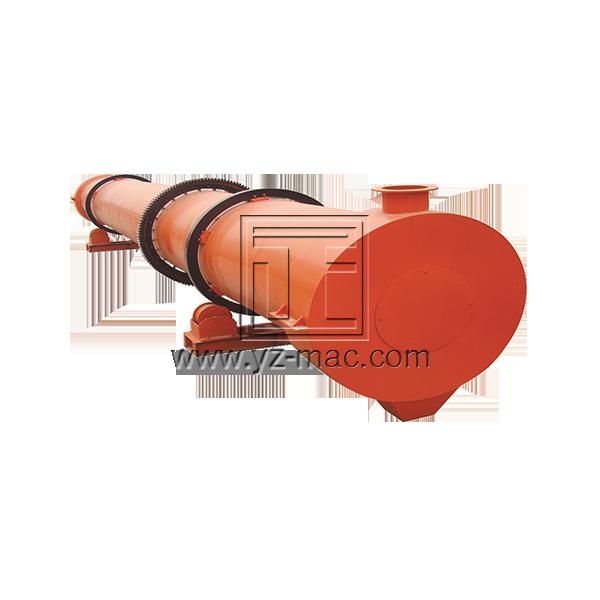

Compost Tumblers:

Compost tumblers are rotating cylindrical containers that provide an enclosed and controlled environment for composting. They are efficient for large-scale composting as they allow for easy mixing and aeration. Compost tumblers are particularly suitable for smaller-sized organic waste materials and can be used in both stationary and mobile setups.

In-Vessel Composting Systems:

In-vessel composting systems involve the use of enclosed containers or vessels that provide a controlled environment for composting. These systems are highly efficient for large-scale composting, allowing for better temperature control, odor management, and shorter composting cycles. In-vessel systems are commonly used in industrial and commercial composting facilities.

Benefits of Large-Scale Composting Equipment:

Increased Composting Efficiency: Large-scale composting equipment helps optimize the composting process by ensuring proper aeration, temperature control, and mixing. This results in faster decomposition and shorter composting cycles, increasing overall composting efficiency.

Consistent Quality: With large-scale composting equipment, it is easier to achieve consistent compost quality. The controlled environment and efficient mixing provided by the equipment ensure uniform decomposition and nutrient distribution throughout the compost pile or windrow.

Reduced Odor and Emissions: Properly designed large-scale composting equipment aids in odor management and reduces the release of greenhouse gases. The equipment promotes aerobic conditions, minimizing the production of foul odors and volatile organic compounds (VOCs), while maximizing the capture of beneficial gases like carbon dioxide.

Enhanced Waste Diversion: Large-scale composting equipment enables the diversion of significant amounts of organic waste from landfills. By composting organic waste materials, valuable resources are recovered and converted into nutrient-rich compost, reducing the reliance on chemical fertilizers and closing the organic waste loop.

Large-scale composting equipment plays a vital role in sustainable waste management by efficiently processing significant volumes of organic waste into high-quality compost. Compost turners, windrow turners, compost tumblers, and in-vessel composting systems are among the essential equipment used in large-scale composting operations. These equipment enhance composting efficiency, promote consistent compost quality, reduce odors and emissions, and contribute to waste diversion from landfills.