Fertilizer mixing plant

A fertilizer mixing plant, also known as a blending facility, is a specialized facility designed to produce customized fertilizer blends by combining different fertilizer components. These plants play a crucial role in the agricultural industry, enabling farmers and fertilizer manufacturers to create tailored nutrient formulations that meet specific crop requirements.

Importance of Fertilizer Mixing Plants:

Fertilizer mixing plants are vital for several reasons:

Customized Nutrient Formulations: Different crops and soil conditions require specific nutrient compositions. Fertilizer mixing plants allow for the precise blending of various fertilizer components, including nitrogen (N), phosphorus (P), potassium (K), micronutrients, and other additives. This customization ensures that the fertilizer applied matches the specific nutrient needs of crops, promoting optimal growth and yield.

Improved Fertilizer Efficiency: By tailoring fertilizer blends, mixing plants can optimize nutrient availability and minimize nutrient losses. Customized formulations ensure that crops receive the right balance of nutrients at the right time, reducing wastage and environmental impact.

Enhanced Soil Health and Nutrient Management: Fertilizer mixing plants enable the creation of blends that address specific soil deficiencies. By incorporating soil analysis data, nutrient imbalances can be corrected, leading to improved soil health and nutrient management practices.

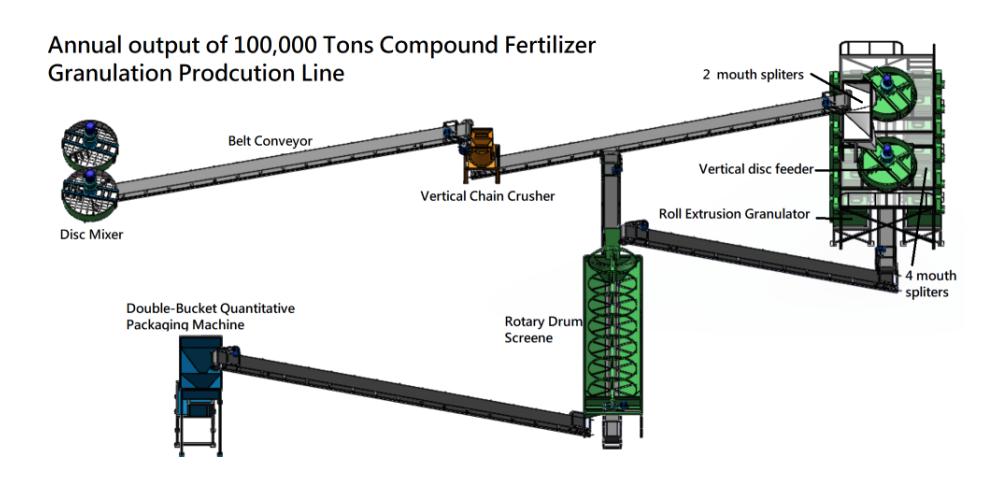

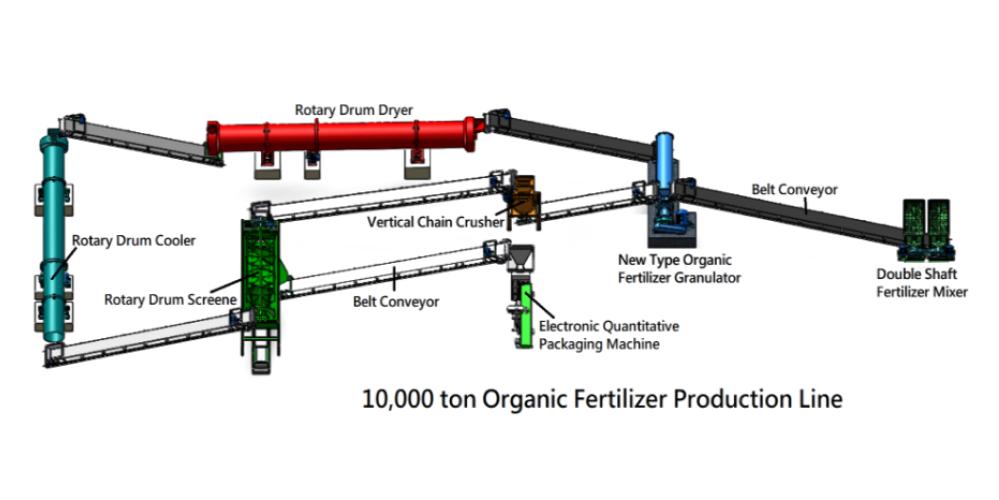

Fertilizer mixing plants typically follow these steps:

Material Handling: Fertilizer components, such as granules, powders, liquids, and additives, are stored in designated silos or tanks. These materials are then conveyed to the mixing area using conveyor belts, augers, or pneumatic systems.

Weighing and Proportioning: Precise weighing systems measure the desired quantities of each fertilizer component based on the formulation requirements. The proportions are carefully controlled to ensure accurate nutrient ratios in the final blend.

Mixing and Homogenization: The weighed fertilizer components are fed into a mixing chamber or blending equipment. Mechanical mixers, such as paddle mixers or rotary drum mixers, are used to thoroughly combine the ingredients, ensuring a uniform blend.

Quality Control: Samples are periodically collected from the blending process to assess the consistency and quality of the fertilizer blend. Quality control measures, including laboratory analysis and visual inspections, are conducted to verify that the product meets the specified standards.

Packaging and Storage: Once the fertilizer blend is deemed satisfactory, it is packaged in bags, sacks, or bulk containers, ready for distribution and storage. Proper labeling and documentation ensure accurate identification and traceability of the fertilizer product.

Benefits of Fertilizer Mixing Plants:

Customization and Flexibility: Fertilizer mixing plants provide the flexibility to create blends with specific nutrient compositions, accommodating the diverse needs of different crops, soil types, and growth stages. This customization allows farmers to optimize nutrient delivery and adapt to changing agricultural practices.

Improved Nutrient Management: Precise blending and formulation control enable farmers to apply nutrients more efficiently, reducing waste and potential environmental impacts. Fertilizer mixing plants support responsible nutrient management practices, ensuring the optimal use of resources.

Enhanced Crop Performance and Yield: Tailored nutrient formulations, produced by mixing plants, support healthy plant growth, improve nutrient uptake, and enhance crop productivity. The availability of customized blends enables farmers to address specific deficiencies and achieve optimal nutrient balance for maximum yield potential.

Quality Assurance: Fertilizer mixing plants employ quality control measures to ensure the consistency, accuracy, and uniformity of the fertilizer blends. This quality assurance guarantees that farmers receive reliable and standardized products, meeting the required nutrient specifications.

Fertilizer mixing plants play a crucial role in the agricultural industry by enabling the production of customized fertilizer blends. These plants ensure precise nutrient formulations, improved fertilizer efficiency, enhanced soil health, and effective nutrient management practices. By tailoring nutrient compositions to specific crop requirements, farmers can optimize nutrient uptake, promote healthy plant growth, and achieve higher yields. Fertilizer mixing plants provide the flexibility, customization, and quality control necessary to meet the evolving demands of modern agriculture, contributing to sustainable and efficient nutrient management practices.