No drying extrusion compound fertilizer production line

A no-drying extrusion compound fertilizer production line is a type of production line that produces compound fertilizer without the need for a drying process. This process is known as extrusion granulation and is an innovative and efficient method of producing compound fertilizers.

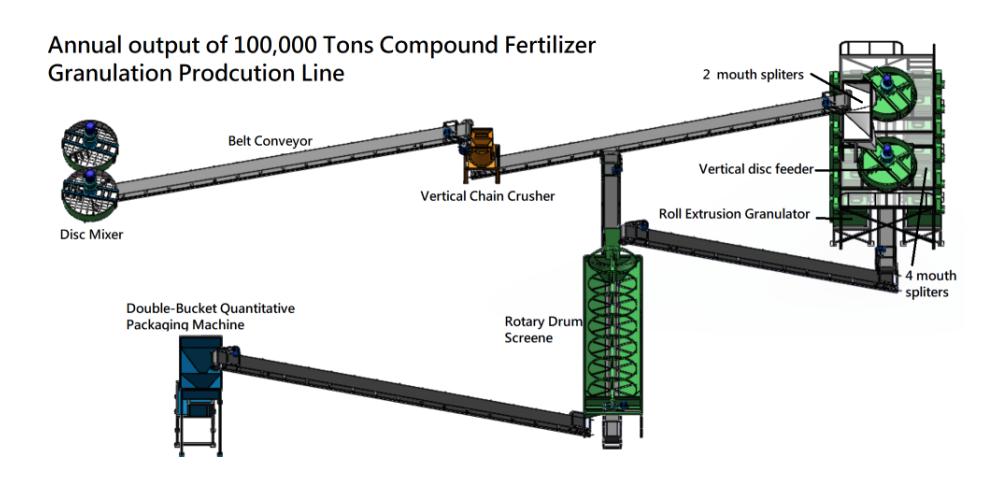

Here is a general outline of a no-drying extrusion compound fertilizer production line:

1.Raw Material Handling: The first step is to collect and handle the raw materials. The raw materials used in the production of compound fertilizer include nitrogen, phosphorus, and potassium (NPK) fertilizers, as well as other organic and inorganic materials such as animal manure, crop residues, and industrial by-products.

2.Crushing: The raw materials are then crushed into small pieces to facilitate the mixing process.

3.Mixing: The crushed raw materials are mixed together using a mixing machine to create a homogeneous mixture.

4.Extrusion Granulation: The mixed materials are then fed into an extrusion granulator, which uses high pressure and a screw or rollers to compress the materials into small pellets or 5.granules. The extruded pellets or granules are then cut to the desired size using a cutter.

6.Screening: The extruded granules are screened to remove any oversize or undersize particles, ensuring a consistent product.

7.Coating: The screened granules are then coated with a layer of protective material to prevent caking and increase storage life. This can be done using a coating machine.

8.Packaging: The final step is to package the granules into bags or other containers, ready for distribution and sale.

It is important to note that the no-drying extrusion compound fertilizer production line is a relatively new technology and may require specific equipment and machinery to produce high-quality granules. However, the advantages of this process include lower energy consumption and reduced environmental impact compared to traditional drying methods.

Overall, a no-drying extrusion compound fertilizer production line can be an efficient and cost-effective way of producing high-quality compound fertilizers with a consistent particle size and nutrient content.