Fertilizer Dryer

A fertilizer dryer is a machine used to remove moisture from granulated fertilizers. The dryer works by using a heated air stream to evaporate moisture from the surface of the granules, leaving behind a dry and stable product.

Fertilizer dryers are an essential piece of equipment in the fertilizer production process. After granulation, the moisture content of the fertilizer is typically between 10-20%, which is too high for storage and transportation. The dryer reduces the moisture content of the fertilizer to a level of 2-5%, which is suitable for storage and transportation.

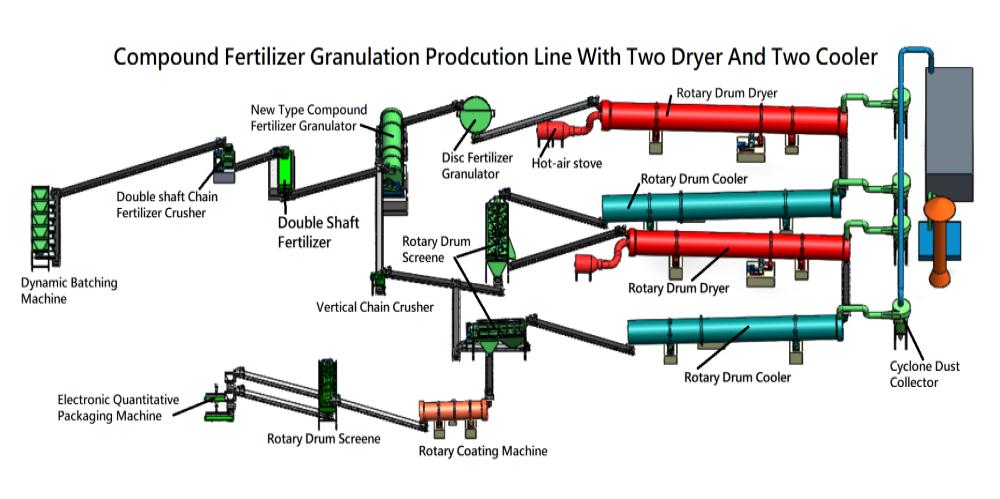

The most commonly used type of fertilizer dryer is the rotary drum dryer, which consists of a large rotating drum that is heated by a burner. The dryer is designed to move the fertilizer through the drum, allowing it to come into contact with the heated air stream.

The dryer’s temperature and airflow can be adjusted to optimize the drying process, ensuring that the fertilizer is dried to the desired moisture content. Once dried, the fertilizer is discharged from the dryer and cooled to room temperature before being packaged for distribution.

In addition to rotary drum dryers, other types of fertilizer dryers include fluidized bed dryers, spray dryers, and flash dryers. The choice of dryer depends on factors such as the type of fertilizer being produced, the desired moisture content, and the production capacity.

When selecting a fertilizer dryer, it is essential to consider factors such as the efficiency, reliability, and ease of maintenance of the equipment. It is also important to choose equipment that is energy-efficient and environmentally friendly.