Duck manure organic fertilizer granulator manufacturer

Duck manure organic fertilizer granulator manufacturer.

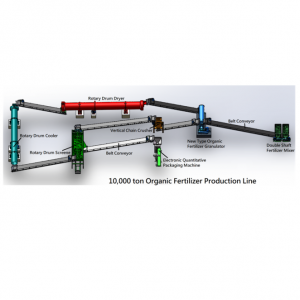

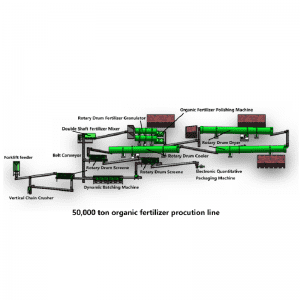

Yizheng Heavy Industry’s main organic fertilizer production line, a complete set of organic fertilizer equipment, has a large-scale equipment production base of 80,000 square meters, can provide a complete set of organic fertilizer equipment, organic fertilizer granulator equipment, organic fertilizer turning machine, fertilizer processing equipment and other complete production equipment .

The granulation process is the core part of the organic fertilizer production line. The granulator is used to produce dust-free particles with controllable size and shape. The granulator achieves high-quality uniform granulation through continuous mixing, collision, inlay, spheroidization, granulation, and compaction processes.

The flat-die extrusion granulator, organic fertilizer stirring tooth granulator, drum granulator, disc granulator, compound fertilizer granulator, buffer granulator, flat die extrusion granulator produced by our company Customers can choose different types of granulators, such as granulators and twin-screw extrusion granulators, according to the actual composting raw materials, sites and products.

The flat die extrusion granulator is one of the main organic fertilizer production equipment. The granular material processed by the machine has a smooth surface, moderate hardness, low temperature rise during processing and can better maintain the nutrients inside the raw material. The flat die extrusion granulator is mainly used in the (biological) organic fertilizer industry to produce fertilizer granules processing machinery.

Flat Die Fertilizer Extrusion Granulator Machine Model Selection:

|

Model |

YZZLPM-150C |

YZZLPM-250C |

YZZLPM-300C |

YZZLPM-350C |

YZZLPM-400C |

|

Production (t/h) |

0.08-0.1 |

0.5-0.7 |

0.8-1.0 |

1.1-1.8 |

1.5-2.5 |

|

Granulating rate (%) |

>95 |

>95 |

>95 |

>95 |

>95 |

|

Granule temperature rise (℃) |

<30 |

<30 |

<30 |

<30 |

<30 |

|

Power (kw) |

5.5 |

15 |

18.5 |

22 |

33 |

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/flat-die-extrusion-granulator-2-product/