The production process of organic fertilizer you want to know

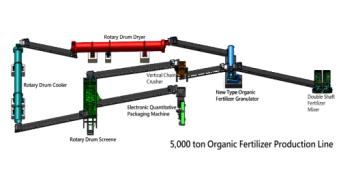

The production process of organic fertilizer is mainly composed of: fermentation process – crushing process – stirring process – granulation process – drying process – screening process – packaging process, etc.

1. First, the raw materials such as livestock manure should be fermented and decomposed.

2. Secondly, the fermented raw materials should be fed into the pulverizer by the pulverizing equipment to pulverize the bulk materials.

3. Add appropriate ingredients in proportion to make organic fertilizer rich in organic matter and improve quality.

4. The material should be granulated after stirring evenly.

5. The granulation process is used to produce dust-free granules of controlled size and shape.

6. The granules after granulation have high moisture content, and can only reach the standard of moisture content by drying in a dryer. The material obtains high temperature through the drying process, and then a cooler is required for cooling.

7. The screening machine needs to screen out the unqualified particles of fertilizer, and the unqualified materials will also be returned to the production line for qualified treatment and reprocessing.

8. Packaging is the last link in the fertilizer equipment. After the fertilizer particles are coated, they are packaged by the packaging machine.