Organic fertilizer production process equipment

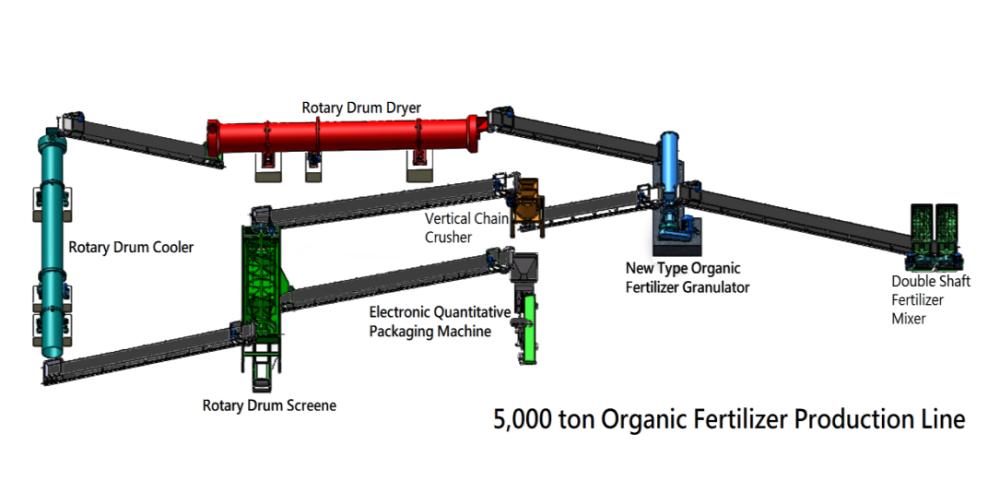

Organic fertilizer production process equipment typically includes equipment for composting, mixing and crushing, granulating, drying, cooling, screening, and packaging.

Composting equipment includes a compost turner, which is used to mix and aerate organic materials, such as manure, straw, and other organic waste, to create a suitable environment for microbial activity and decomposition.

Mixing and crushing equipment includes a horizontal mixer and a crusher, which are used to blend and crush raw materials to create a homogenous mixture suitable for granulation.

Granulation equipment includes an organic fertilizer granulator, which is used to shape and form the raw material mixture into small, uniform granules.

Drying equipment includes a rotary dryer and a cooling machine, which are used to dry and cool the granules to an appropriate moisture level.

Screening equipment includes a vibrating screen, which is used to separate the granules into different sizes based on their diameter.

Packaging equipment includes an automatic packing machine, which is used to weigh, fill, and seal the final product into bags or other containers.

Other supporting equipment may include conveyor belts, dust collectors, and auxiliary equipment for process control and monitoring.