Organic Fertilizer Manufacturing Process

The organic fertilizer manufacturing process typically involves the following steps:

1.Raw Material Preparation: This involves sourcing and selecting the appropriate organic materials such as animal manure, plant residue, and food waste. The materials are then processed and prepared for the next stage.

2.Fermentation: The prepared materials are then placed in a composting area or a fermentation tank where they undergo microbial degradation. The microorganisms breakdown the organic materials into simpler compounds that can be easily absorbed by the plants.

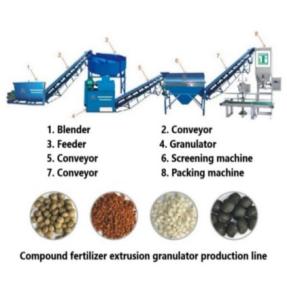

3.Crushing and Mixing: The fermented organic material is then crushed into smaller particles and mixed thoroughly to ensure a uniform distribution of nutrients.

4.Granulation: The mixed organic material is then fed into a granulation machine where it is shaped into small granules. This process makes it easier to store and transport the fertilizer.

5.Drying: The granulated fertilizer is then dried to reduce the moisture content. This process also helps to increase the shelf life of the fertilizer.

6.Cooling: After drying, the fertilizer is then cooled to room temperature to prevent caking and ensure the granules retain their shape.

7.Screening and Packaging: The cooled fertilizer is screened to remove any oversized particles and then packaged into appropriate bags or containers.

The organic fertilizer manufacturing process is a complex but important process that ensures the production of high-quality organic fertilizers that are beneficial for plant growth and soil health.