Organic fertilizer manufacturing equipment

There are various types of equipment that can be used in the manufacturing of organic fertilizer. Some of the most common types of organic fertilizer manufacturing equipment include:

1.Composting equipment: This includes compost turners, compost bins, and other equipment used to facilitate the composting process.

2.Crushing and mixing equipment: This includes crushers, mixers, and other equipment used to crush and mix the organic materials.

3.Granulation equipment: This includes organic fertilizer granulators, disc granulators, and other equipment used to transform the mixed materials into small, uniform granules or pellets.

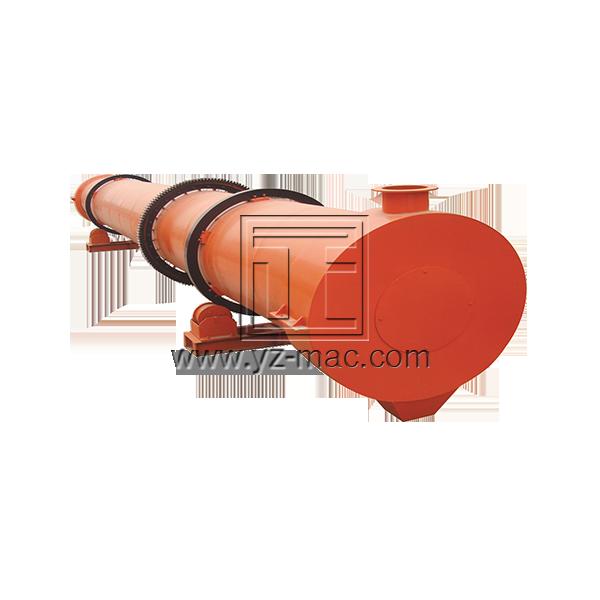

4.Drying and cooling equipment: This includes rotary drum dryers and coolers, fluidized bed dryers, and other equipment used to remove excess moisture from the granules.

5.Screening equipment: This includes rotary drum screens, vibrating screens, and other equipment used to screen the granules to remove any oversized or undersized particles.

6.Coating equipment: This includes coating machines used to apply a thin layer of protective coating to the granules.

7.Packaging equipment: This includes bagging machines, weighing scales, and other equipment used to package the finished product.

The specific equipment used in organic fertilizer manufacturing can vary depending on the production capacity, the specific type of fertilizer being produced, and other factors.