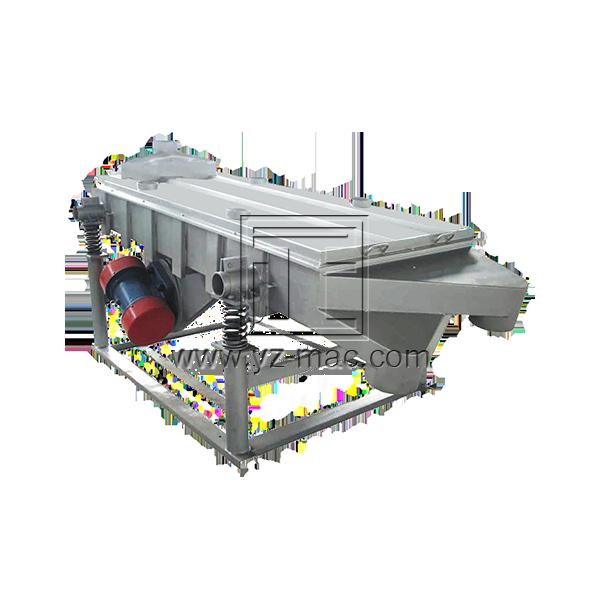

Organic Fertilizer Classifier

An organic fertilizer classifier is a machine that is used to sort organic fertilizers based on particle size, density, and other properties. The classifier is an important piece of equipment in organic fertilizer production lines because it helps to ensure that the final product is of high quality and consistency.

The classifier works by feeding the organic fertilizer into a hopper, where it is then transported onto a series of screens or sieves that separate the fertilizer into different particle sizes. The screens may have different-sized holes or meshes that allow certain-sized particles to pass through while retaining larger particles. The screens may also be set at different angles to help separate particles based on their density or shape.

In addition to screens, the classifier may also use air currents or other methods to separate particles based on their properties. For example, air classifiers use air currents to separate particles based on their density, size, and shape.

Organic fertilizer classifiers are typically made of durable materials such as stainless steel or other corrosion-resistant alloys. They are available in a range of sizes and capacities to accommodate different production needs.

Using an organic fertilizer classifier can help increase production efficiency and ensure consistent quality of the final product by removing any unwanted particles or debris from the fertilizer.