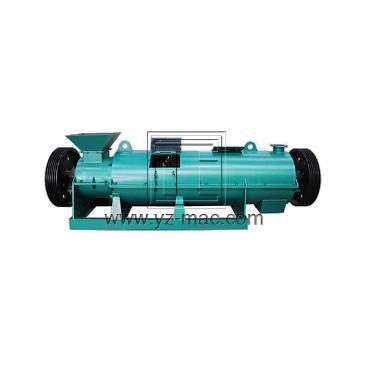

organic compost mixer supplier

Send email to us

Previous:

Organic compost mixing equipment price

Next:

Organic fertilizer mixer factory price

There are many organic compost mixer suppliers around the world, offering a variety of compost mixing equipment to meet the needs of gardeners, farmers, and other agricultural businesses.

>Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

When choosing an organic compost mixer supplier, it is important to consider factors such as the quality and reliability of the equipment, the level of customer support and service provided, and the overall cost and value of the equipment. It may also be helpful to read reviews and testimonials from other customers to get a better idea of the supplier’s reputation and track record.

Write your message here and send it to us