NPK fertilizer granulator

An NPK fertilizer granulator is a specialized machine designed to transform NPK fertilizers into granular form, making them easier to handle, store, and apply. NPK fertilizers, which contain essential nutrients nitrogen (N), phosphorus (P), and potassium (K), play a crucial role in promoting healthy plant growth and maximizing crop yields.

Benefits of NPK Fertilizer Granulation:

Enhanced Nutrient Efficiency: Granular NPK fertilizers have a controlled release mechanism, allowing for a slow and steady release of nutrients over an extended period. This promotes better nutrient absorption by plants, minimizes nutrient leaching, and reduces the risk of nutrient loss through volatilization, thereby improving overall nutrient use efficiency.

Ease of Handling and Application: The granular form of NPK fertilizers makes them convenient to handle and apply. Granules are uniform in size, making them flow smoothly through seeding equipment and fertilizer spreaders, ensuring even distribution across the field. This results in precise nutrient placement and reduces the risk of over- or under-fertilization.

Improved Nutrient Distribution: Granular NPK fertilizers provide a balanced distribution of nutrients within each granule. This uniformity ensures that plants receive a consistent supply of essential elements, minimizing nutrient deficiencies and optimizing plant growth and development.

The Granulation Process:

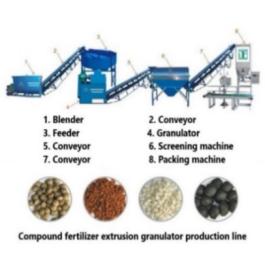

NPK fertilizer granulation involves several steps to convert powdered or liquid NPK fertilizers into granules:

Mixing: The NPK fertilizer components, including nitrogen, phosphorus, and potassium sources, are thoroughly mixed to achieve a homogeneous blend. This ensures that each granule contains a balanced ratio of nutrients.

Granulation: The mixed fertilizer material is fed into an NPK fertilizer granulator, where it undergoes granulation. The granulator combines the powdered or liquid fertilizer with a binding agent, which helps form granules of the desired size and shape.

Drying: After granulation, the newly formed NPK fertilizer granules may contain excess moisture. They are then dried to remove the moisture, enhancing the stability and storage life of the granules.

Cooling and Screening: The dried granules are cooled to room temperature to prevent moisture absorption. They are then screened to separate oversized or undersized granules, ensuring uniformity in size and improving product quality.

Advantages of Granular NPK Fertilizers:

Controlled Release: Granular NPK fertilizers release nutrients gradually, providing a continuous supply to plants throughout their growth cycle. This reduces the risk of nutrient leaching, increases nutrient use efficiency, and minimizes the need for frequent fertilizer applications.

Precision in Nutrient Application: Granular NPK fertilizers allow for precise nutrient placement, minimizing the risk of nutrient wastage and environmental pollution. This targeted application ensures that nutrients reach the root zone of plants, maximizing their uptake and utilization.

Compatibility with Blending: Granular NPK fertilizers can be easily blended with other granular or bulk fertilizers, micronutrients, or soil amendments to create custom fertilizer blends tailored to specific crop requirements. This flexibility allows for nutrient customization and improved crop management practices.

An NPK fertilizer granulator offers numerous benefits in enhancing nutrient efficiency, ease of handling, and precision in nutrient application. The granulation process converts NPK fertilizers into granules, which provide controlled nutrient release, improved nutrient distribution, and compatibility with blending practices. The advantages of granular NPK fertilizers include enhanced nutrient uptake by plants, reduced nutrient losses, and efficient use of fertilizers.