First raw chicken manure is not equal to organic fertilizer. Organic fertilizer refers to straw, cake, animal and poultry manure, mushroom slag and other fertilizer processed by rotting fermentation. Livestock manure is only a raw material for the production of organic fertilizer, and is one of the lower endofof of all raw materials.

No matter wet and wet chicken manure, unfermented are easy to cause greenhouse vegetables, orchards and other cash crops devastating disaster, to farmers caused huge economic losses. Let's first understand the dangers of untreated chicken manure, and finally we say why we think raw chicken manure is more effective than other animal manure. More effective force?

Eight disasters that can easily cause from the use of chicken manure in greenhouse vegetables and orchards:

Burning roots, burning seedlings, smoking trees, dead strains

After using chicken manure that is not thoroughly fermented, insert the hand into the soil and feel the soil temperature is higher. Serious film or full of dead, when the loss of labor costs and seedling investment.

Especially in winter and spring the application of chicken manure safety risk is the largest, because at this time the high temperature in the shed, chicken manure fermentation will emit a lot of heat, resulting in the burning of root phenomenon;

Salinization of soil in the shed, fruit reduction

Years of use of chicken manure, soil left a large number of sodium chloride salts, an average of 6 square chicken manure salt content of 30-40 kg, and 10 kg of salt per acre has seriously restricted soil permeability and activity, curing phosphorus fertilizer, potassium fertilizer, calcium and zinc iron boron manganese and other important elements, plant growth abnormal, flower buds, fruit not open and other production reduction phenomenon, significantly restricting crop yield and quality improvement.

As a result, fertilizer utilization rate plummeted, less than one year, increased input costs 50-100%;

Acidification of soil, induced various root diseases and viral diseases

Because the pH of chicken manure is about 4, is extremely acidic, acidified soil, resulting in chemical trauma and serious damage to the stem base and root tissue, to the chicken manure carrying a large number of viral bacteria, soil-borne disease bacteria, viruses provide an entry and infection opportunities, in the humidity and temperature once reached will break out of the disease.

The use of fermentation is not complete chicken manure, very easy to cause plant wilt, yellow, shrinkage is not long, fig, even death;

Breeding root knot nematodes

Chicken manure is a bedpit and hotbed of root knot nematodes, the number of their own carrying root knot nematode eggs per 1000 grams 100, chicken manure nematode eggs are easy to hatch, overnight doubled tens of thousands, the incidence of nematodes in the soil in the land with chicken manure increased by more than 500 times.

Bitter melon root knot nematodes

Nematodes are extremely sensitive to chemicals, and after administration nematodes quickly move to a depth of 50 cm -1.5 meters underground to escape, so it is difficult to cure them. Especially for more than 3 years old sheds, root knot nematodes are one of the most deadly hidden dangers.

Bringing antibiotics, affecting the safety of agricultural products

Chicken breeding process, feed China contains a lot of hormones, disease prevention and treatment will also use antibiotics, these will be brought into the soil through chicken manure, affecting the safety of agricultural products.

Produce harmful gases, smoke trees, die

Produce harmful gases, smoked trees, dead slugs: chicken manure in the decomposition process to produce methane, ammonia and other harmful gases, so that soil and crops produce acid damage and root damage, more serious is the production of ethylene gas inhibited root growth, is also the main cause of root burning.

Years of use of chicken manure, resulting in a lack of oxygen in the root system

Years of use of chicken manure, resulting in root system lack of oxygen, growing bad, chicken manure cast into the soil, in the decomposition process to consume oxygen in the soil, so that the soil temporarily in the state of hypoxia, will make crop growth inhibited.

Heavy metals exceed the standard

Heavy metals exceed the standard: chicken manure contains a high amount of copper, mercury, chromium, cadmium, lead, arsenic and other heavy metals, there are more hormone residues, resulting in heavy metals in agricultural products exceeded the standard, pollution of groundwater sources and soil, organic matter to humus for a longer time, nutrient loss is serious.

Why is it so strong with chicken manure?

This is because chicken rectal things, urine together, so chicken manure contains 25.5% of the organic matter, contains more than 60% of the organic matter is in the form of uric acid, uric acid decomposition after providing a large number of nitrogen elements, the use of a thousand pounds of chicken manure equivalent to the application of 153 pounds of urea, the surface looks natural long and robust crops. If this happens on eggplant or fruit tree grapes, severe physiological diseases can occur.

Mainly because of nitrogen and trace elements of antagonism, urea donots too much, will cause a variety of trace elements absorption blocked, the production of yellow leaves, umbilical rot, cracking fruit, chicken claw disease and so on.

We see the chicken manure is not rotting eight harms, compare, look at your orchard or vegetable garden, there is no often burning seedlings rotten root dead tree, fertilizer is not less, yield and quality is not going up, and even the long half of the dead, soil knot, heavy stoics and so on bad situation. Chicken manure needs to be fermented and harmlessly treated to be applied to the soil!

Reasonable and effective use of chicken manure

Chicken manure is a very good organic fertilizer raw material, rich in pure nitrogen about 1.63%, phosphorus (P2O5) about 1.54%, potassium (K2O) about 0.085%,can be processed with professional organic fertilizer production equipment into organic fertilizer, after the chicken manure organic fertilizer production line fermentation process, harmful insects and weed seeds with the temperature rise and fall, will be eliminated. The production line of chicken manure organic fertilizer includes: fermentation, crushing, mixing of ingredients, granulation, drying, cooling screening, metering sealing, finished product storage.

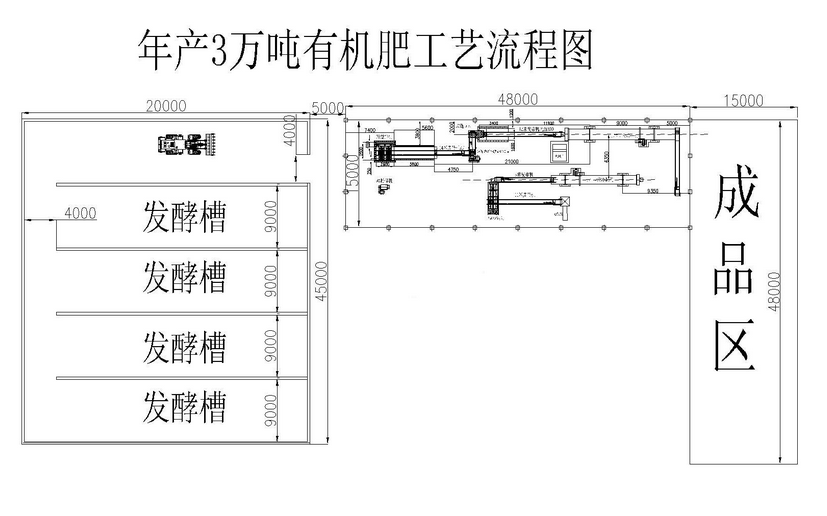

Organic fertilizer production process flow chart

Organic fertilizer production process

First, the raw material area to build four fermentation tanks, each 40m long, 3m wide, 1.2m deep, the common area of 700m 2;

Second, the raw material area needs to buy light rail 320m;

Third, the land area of the production area 1400m 2;

Fourth, the raw material area needs to use production personnel 3 people, production area needs to use 20 people;

Fifth, the raw material area needs to buy three tons of forkliftone one.

Introduction to the main equipment of chicken manure organic fertilizer production line

1, chicken manure organic fertilizer pre-fermentation equipment: slot-type dumper, track-type dumper, self-walking dumper, chain board-type dumper

2, chicken manure organic fertilizer shredder equipment: semi-wet material shredder, chain shredder, vertical shredder

3, chicken manure organic fertilizer mixer equipment: horizontal mixer, disc mixer

4, chicken manure organic fertilizer sieve machine equipment: roller sieve machine, vibration sieve extension

5, chicken manure organic fertilizer granulation machine equipment: stirring teeth granulation machine, disc granulation machine, extrusion granulation machine, drum granulation machine, rounding machine

6, chicken manure organic fertilizer dryer equipment: tumble dryer

7, chicken manure organic fertilizer cooling machine equipment: rotary cooling machine

8, chicken manure organic fertilizer supporting equipment: quantitative feeding machine, pig manure dewatering machine, wrap machine, dust remover, automatic quantitative packaging machine

9, chicken manure organic fertilizer conveyor equipment: belt conveyor, bucket lifter.

General organic fertilizer production process design includes:

1, efficient compound species and its expansion technology;

2, advanced raw material smelting technology and biofermentation system;

3, the best special fertilizer formula technology (can be flexible according to the local soil and crop characteristics, the best combination of product formulation);

4, reasonable secondary pollution (exhaust gas and odor) control technology;

5, fertilizer complete sets of technology design and manufacturing technology.

Precautions in the production of organic fertilizer for chicken manure:

Fineness of the raw material:

A reasonable matching of the fineness of raw materials is essential to the production process of organic fertilizer. According to experience, the fineness of the whole raw material should be matched with the following: 100-60 purpose raw materials about 30%-40%, 60 eye to diameter 1.00mm raw material stake about 35%, diameter 1.00-2.00mm small particles about 25%-30%, the higher the fineness of the material, the better the viscosity, the higher the finish of the particle surface after granulation. However, in the production process, the use of a super-proportion of high-precision materials, easy to appear due to the viscosity of too good resulting in particles too large, particle irregularities and other issues.

The standard of rotting chicken manure fermentation (grab a handful of material, land and scatter)

Chicken manure must be thoroughly cooked before application, the presence of parasites in chicken manure and their eggs, , and infectious bacteria through the process of decay (cocite) to be inactivated, after full decay, chicken manure will become a high-quality base fertilizer for growing crops.

1. Rotting

At the same time with the following three, you can generally judge that chicken manure has been basically fermented well.

1. Basically can't smell; 2. There is white mycelium; 3. chicken manure into a loose shape.

The time of decay is generally: natural conditions generally last about 3 months, if the addition of fermentation agent, this process will be greatly accelerated, depending on the ambient temperature, generally need 20 to 30 days, if the conditions of factory production 7 to 10 days can be completed.

2. Humidity

Regulate the moisture content before the chicken manure is fermented. In the process of fermenting organic fertilizer, it is very important to see whether the moisture content is suitable. Because the rotting agent inside are live bacteria, if too dry or too wet will affect the fermentation of microorganisms, generally should be kept at 60 to 65%.

Method of judgment: hand graspa a material, finger seam watermark but not dripwater, the floor can be dispersed as appropriate.

Post time: Sep-22-2020