At present, organic fertilizer use accounts for about 50% of the total fertilizer use in Western countries. People pay more attention to food safety in developed areas. The greater the demand for organic food, the greater the demand for organic fertilizers. According to the development characteristics of organic fertilizer and market trends organic fertilizer market prospects are broad.

Our small production capacity organic fertilizer production line provides you with fertilizer production and installation guides, organic fertilizer production processes and technologies. For fertilizer investors or farmers If you have little information about organic fertilizer production and no customer sources, you can start with a small organic fertilizer production line.

MINI organic fertilizer production lines range in fertilizer production capacity from 500 kg to 1 ton per hour.

For the production of organic fertilizers, there are many raw materials available: .

1. animal feces: chicken manure, pig manure, sheep manure, cattle singing, horse manure, rabbit manure and so on.

2. industrial waste: grapes, vinegar slag, cassava slag, sugar slag, biogas waste, fur slag and so on.

3. agricultural waste: crop straw, soybean powder, cotton seed powder and so on.

4. household waste: kitchen garbage.

5. sludge: urban sludge, river sludge, filter mud, etc.

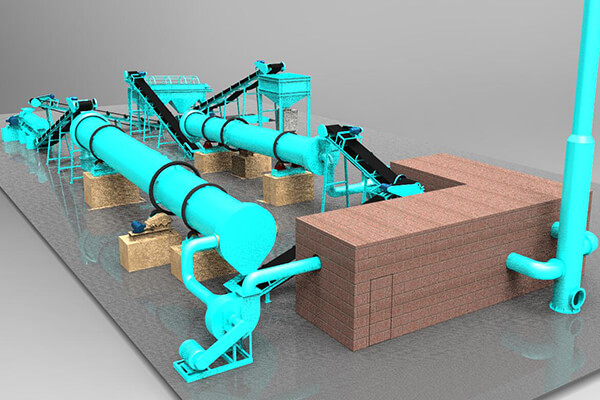

Small organic fertilizer production line.

1. Walking compost machine.

When you make organic fertilizer, the first step is to compost and break down some of the ingredients. Self-walking composting machines are widely used in composting. Its main function is to rotate and mix organic materials. As a result, the fermentation process is accelerated and the entire compost takes only 7-15 days.

|

Model |

Width pile (mm) |

Height heap (mm) |

Pile distance (meters) |

Power (Water cool, electrically started) |

Processing capacity(m3/h) |

Driving. Mode. |

|

9FY – World -2000 |

2000 |

500-800 |

0.5-1 |

33FYHP |

400-500 |

Forward 3rd gear; 1st gear back. |

2. Chain crusher.

After fermentation, organic fertilizer raw materials need to be crushed, especially sludge, biogas digesters, animal waste, solid water and so on. This machine.

can crush up to 25-30% of organic matter with high water content.

|

Model. |

The overall dimension. (mm) |

Production capacity(t/h).) |

Motor power (kW) |

Maximum size entry particles (mm) |

Size after crushing (mm) |

|

FY-LSFS-60. |

1000X730X1700 |

1-5 |

15 |

60 |

<±0.7 |

3. Horizontal blender .

Horizontal mixers can mix organic fertilizer raw materials, feed, concentrated feed, additive premixes, etc. In addition, it can be used to mix two kinds of fertilizer. Even if the fertilizer material is different in gravity and size, it can achieve a good mixing effect.

|

Model. |

Capacity(t/h).) |

Power (kW) |

Overall size (mm) |

|

FY-WSJB-70 |

2-3 |

11 |

2330 x 1130 x 970 |

4. New organic fertilizer granulation machine.

The new organic granulation machine is used for chicken manure, pig manure, cow dung, black carbon, clay, kaolin and other particles granulation. Fertilizer particles can be up to 100% organic. Particle size and uniformity can be adjusted according to the unseeded speed adjustment function.

|

Model. |

Capacity(t/h).) |

Granulation ratio. |

Motor power (kW) |

Size L-W – High (mm). |

|

FY-JCZL-60 |

2-3 |

-85% |

37 |

3550 x 1430 x 980 |

5. Sieve the divider.

The new organic fertilizer sieve is used to separate standard fertilizer particles from substandard fertilizer particles.

|

Model. |

Capacity(t/h).) |

Power (kW) |

Inclination(0).) |

Size L-W – High (mm). |

|

FY-GTSF-1.2X4 |

2-5 |

5.5 |

2-2.5 |

5000 x 1600 x 3000 |

6. Automatic packaging machine.

Use an automatic fertilizer packer to package organic fertilizer particles at approximately 2to50 kg per bag.

|

Model. |

Power (kW) |

Voltage(V). |

Air source consumption(m3/h). |

Air source pressure(MPa). |

Packaging(kg). |

Packing pace bag / m. |

Packaging accuracy. |

Overall size. L-W-H (mm). |

|

DGS-50F |

1.5 |

380 |

1 |

0.4-0.6 |

5-50 |

3-8 |

-0.2-0.5% |

820 x 1400 x 2300 |

Post time: Sep-28-2020