Food waste has been increasing as the world's population has grown and cities have grown in size. Millions of tons of food are thrown into garbage dumps around the world every year. Nearly 30% of the world's fruits, vegetables, grains, meats and packaged foods are thrown away each year. Food waste has become a huge environmental problem in every country. Large amounts of food waste cause serious pollution, which damages air, water, soil and biodiversity. On the one hand, food waste breaks down anaerobicly to produce greenhouse gases such as methane, carbon dioxide and other harmful emissions. Food waste produces the equivalent of 3.3 billion tons of greenhouse gases. Food waste, on the other hand, is thrown into landfills that take up large tracts of land, producing landfill gas and floating dust. If the leachate produced during landfill is not handled properly, it will cause secondary pollution, soil pollution and groundwater pollution.

Incineration and landfill have significant disadvantages, and further use of food waste will contribute to environmental protection and increase the utilization of renewable resources.

How food waste is produced into organic fertilizer.

Fruits, vegetables, dairy products, cereals, bread, coffee grounds, eggshells, meat and newspapers can all be composted. Food waste is a unique composting agent that is a major source of organic matter. Food waste includes chemical elements such as starch, cellulose, protein lipids and inorganic salts, as well as trace elements such as、、、、、 N,P,、K,Ca,Mg,Fe,K, etc. Food waste is up to 85% biodegradable. It has the characteristics of high organic content, high water content and abundant nutrients, and has high recycling value. Because food waste has the characteristics of high moisture content and low density physical structure, it is important to mix fresh food waste with puffing agent, which absorbs excess water and adds structure to mix.

Food waste has high levels of organic matter, with crude protein accounting for 15% - 23%, fat for 17% - 24%, minerals for 3% - 5%, Ca for 54%, sodium chloride for 3% - 4%, etc.

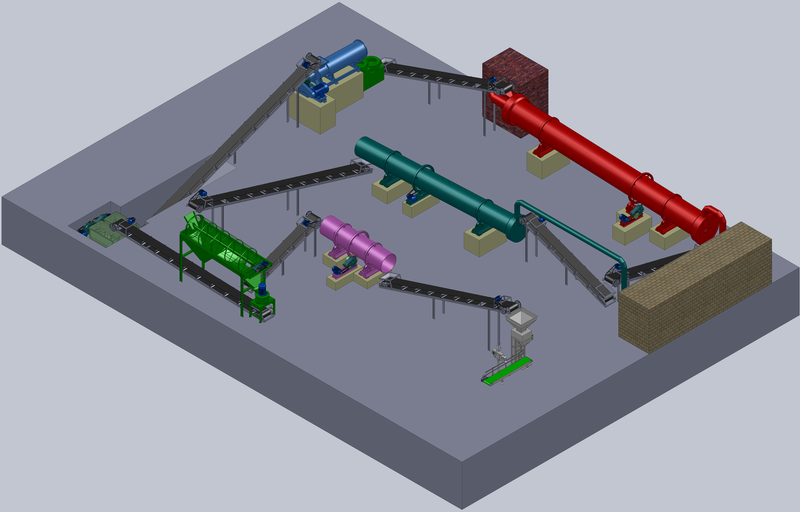

Process technology and related equipment for the conversion of food waste into organic fertilizer.

It is well known that the low utilization rate of landfill resources causes pollution to the environment. At present, some developed countries have established a sound food waste treatment system. In Germany, for example, food waste is treated mainly through composting and anaerobic fermentation, producing about 5 million tons of organic fertilizer from food waste each year. By composting food waste in the UK, about 20 million tonnes of CO2 emissions can be reduced each year. Composting is used in almost 95% of U.S. cities. Composting can bring a variety of environmental benefits, including reducing water pollution, and the economic benefits are considerable.

Dehydration.

Water is the basic component of food waste accounted for 70%-90%,is the root cause of food waste quality. Therefore, dehydration is the most important link in the process of converting food waste into organic fertilizer.

The food waste pre-treatment device is the first step in the treatment of food waste. It mainly includes: oblique sieve dewatering machine, splitter, automatic separation system, solid liquid separator, oil and water separator, fermentation tank.

The basic process can be divided into the following sections: .

1. Food waste must be pre-dehydrated first because it contains too much water.

2. Removal of inororable waste from food waste, such as metals, wood, plastics, paper, fabrics, etc., through sorting.

3. Food waste is selected and fed into a spiral solid liquid separator for crushing, dehydration and degreasing.

4. Squeezed food residues are dried and sterilized at high temperatures to remove excess moisture and various pathogenic microorganisms. The fineness and dryness of the food waste required for composting, as well as food waste, can be fed directly into the fermentation tank through a belt conveyor.

5. Water removed from food waste is a mixture of oil and water, separated by an oil-water separator. The separated oil is processed deep to obtain biodiesel or industrial oil.

The device has the advantages of high output, safe operation, low cost and short production cycle. Through the harmless treatment of reduced resources and food waste, secondary pollution caused by food waste in the transportation process is avoided. There are many models to choose from in our factory, such as 500kg/h, 1t/h, 3t/h, 5t/h, 10t/h, etc.

Compost.

Fermentation tank is a kind of fully enclosed fermentation tank using high temperature aerobic fermentation technology, which replaces the traditional stacking composting technology. The closed high temperature and fast composting process in the tank produces high-quality compost, which can be controlled more precisely, decomposed faster and the product quality is more stable.

The compost in the container is thermally isolated, and temperature control during composting is key. By maintaining optimal temperature conditions for microbial activity, organic matter can be quickly decomposed and high temperature sterilization, eggs and weed seeds can be achieved simultaneously. Fermentation is initiated by naturally occurring microorganisms in food waste that break down composting materials, release nutrients, raise the temperature to 60-70 degrees C required to kill pathogensandweed seeds,and comply with regulations for thetreatment of organic waste. Food waste can be composted in just 4 days using fermentation tanks. After only 4-7 days, the compost is thoroughly rotted and discharged, and the rotten compost has no odor and is disinfected to be rich in organic nutrient balance. This production of compost tasteless, sterile, not only save landfill land to protect the environment, but also will bring some economic benefits.

Granulation.

Particulate organic fertilizer occupies an important position in the fertilizer market around the world. The key to improve the production capacity of organic fertilizer is to select the right organic fertilizer granulation machine. Granulation is the process of forming small particles of organic raw materials, which can improve the performance of organic raw materials to prevent the blocks from increasing mobility, so that small-volume applications may be easy to load, transport and so on. All raw materials can be formed into round organic fertilizers through our organic fertilizer granulation mechanism. Material granulation rates can be up to 100% andorganic content can be ashigh as 100%.

For large-scale farming, granularity for market use is essential. Our machines can produce organic fertilizers of 0.5mm-1.3mm,、1.3mm-3mm,、2mm-5mm in different sizes. The granulation of organic fertilizers provides some of the most feasible ways to mix minerals to produce a variety of nutritious fertilizers, allowing large quantities to be stored and packaged for easy commercialization and application. Granular organic fertilizers are easy to use without unpleasant odors, weed seeds and pathogens, and their composition is well known. Compared to animal waste, Their nitrogen N content is 4.3 times that of the former, the content of phosphorus P2O5 is 4 times that of the latter, and the content of potassium K2O is 8.2 times that of the latter. Particulate organic fertilizer improves soil productivity, soil physical, chemical, microbiological properties and humidity, air and heat by increasing humus level, while increasing crop yield.

Dry and cool.

During the production of organic fertilizer, both the tumble dryer and the cooler are used in combination. Reducing the moisture of organic fertilizer particles and reducing the temperature of the particles to achieve the goal of sterilizing deodorization. These two steps minimize nutrient loss in organic fertilizer to make the particles more uniform and smooth.

Sieve the package.

The screening process is carried out by the roller sieve subsecond to filter out nonconforming particles. Non-conforming particles will be transported by the conveyor to the blender for reprocessing, and qualified organic fertilizer will be packaged by the automatic packaging machine.

Benefit from organic fertilizer in food.

Converting food waste into organic fertilizers can create economic and environmental benefits that can improve soil health and help reduce erosion and improve water quality. Renewable natural gas and biofuels can also be produced from recycled food waste, which can help reduce greenhouse gas emissions and dependence on fossil fuels.

Organic fertilizer is the best nutrient for soil and has many benefits for soil. It is a good source of plant nutrition, including nitrogen, phosphorus, potassium and micronutrients, which are necessary for plant growth. It can also control some plant pests and diseases, but also reduce the need for a variety of fungicides and chemicals. High-quality organic fertilizers will be used in a wide range of fields, including flower displays in agriculture, farms and public spaces, which will also bring direct economic benefits to producers.

Post time: Sep-22-2020