One of the major advantages to working with Yi Zheng is our complete system knowledge; we’re not just experts in one part of the process, but rather, every component. This allows us to provide our customers with a unique perspective on how each part of a process will work together as a whole.

We can provide complete granulation systems, or individual pieces of equipment for both inorganic and organic applications.

COMPLETE PROCESS SYSTEMS

One of the major advantages to working with Yi Zheng is our complete system knowledge; we’re not just experts in one part of the process, but rather, every component. This allows us to provide our customers with a unique perspective on how each part of a process will work together as a whole.

FERTILIZER GRANULATION SYSTEMS

We can provide complete granulation systems, or individual pieces of equipment for both inorganic and organic applications.

ORGANIC FERTILIZER MAKING PLANT

-Cattle Manure

-Dairy Manure

-Hog Manure

-Chicken Manure

-Sheep Manure

-Municipal Sewage Sludge

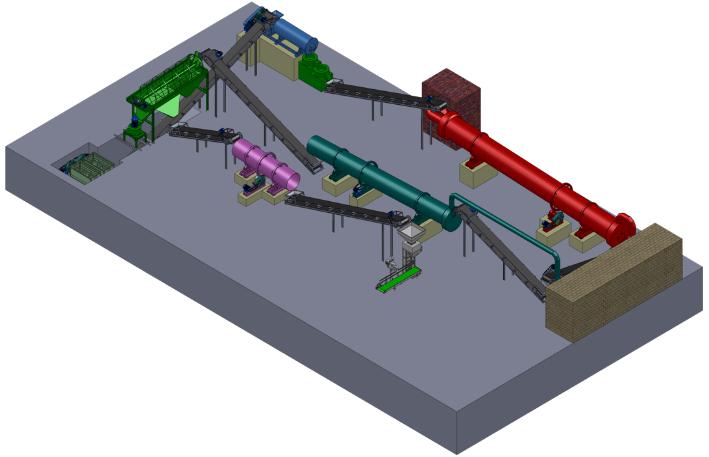

We can provide the process design and supply of a stirring tooth granulator

System for producing organic fertilizer. Equipment included a Hopper &

Feeder, Stirring Tooth Granulator, Dryer, Rotary Screen, Bucket Elevator, Belt

Conveyor, Packing Machine and Scrubber.

Raw Materials of Organic Fertilizer can be methane residue, agricultural waste, animal manure, and MSW. While all those organic waste need to be further processed before being turned into products with sales value. The large investment in Turning Trash into Treasure is absolutely well worth the money.

Advantages:

1. Equipped with advanced fertilizer manufacturing technique, this bio fertilizer production line can finish organic fertilizer manufacturing in one process.

2. Adopts advanced new type organic fertilizer dedicated granulator, granulating ratio is up to 70%, high intensity of granules,

3. Wide adaptability of raw materials

4. Stable performance, anti-corrosion and wear-resistant materials components, abrasion proof, low energy consumption, long service lifespan, easy maintenance and operation, etc.

5. High efficiency and economic returns, and the small part of feeding back material can be granulated again.

6. Adjustable capacity according to customers’ requirements.

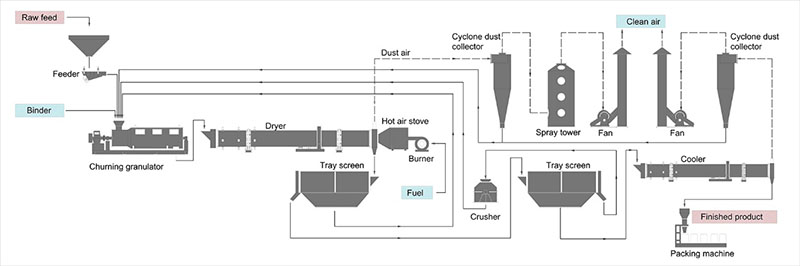

Production process flow:

Fermentation system, disc mixer, new type organic fertilizer granulator, rotary drum dryer, rotary cooler, rotary drum screening machine, storage bin, full automatic packaging machine, vertical crusher, and belt conveyor. Animal manure, SMW, and crop straw as raw materials of organic fertilizer, the whole organic fertilizer manufacturing process consists of: materials crushing→ fermentation→ blending (mixing with other organic-inorganic materials, NPK≥4%, organic matter ≥30%)→granulation → packaging

NOTICE: This production line is for your reference only.

1)Fermentation Process:

Lane turner is the most widely-used fermentation turning equipment. This compost windrow turner includes fermentation groove, walking track, electricity system, turning components and multi-tank system. Fermentation and turning parts adopt advanced roller drive. The fermentation equipment of hydraulic fertilizer turner can be raised and lowered freely.

2)Granulation Process

New organic fertilizer granulation machine is widely used in organic fertilizer granulation, and it is the dedicated fertilizer pellet mill to granulate organic waste, such as animal manure, rotten fruit, fruit peels, raw vegetables, green manure, sea manure, farmyard manure, three waste and microorganisms etc. Due to high granulation rate, stable operation, durable equipment and long service life, it has been the ideal choice for organic fertilizer production. The shell of this fertilizer pellet mill are made of seamless tubes, more durable and never deformation. Coupled with secure base design, making this machine run more stable. The compressive strength of new type granulator is higher than disc granulator and rotary drum granulator. Size of particles is adjustable in accordance with customers’ requirements. This fertilizer granulator is most suitable for direct-granulation after organics fermentation, saving drying process, and greatly reducing the production cost.

3)Fertilizer Drying and Cooling Process

The granular fertilizer formed by the fertilizer granulator has high moisture content and shall be dried to meet the standard. Rotary drum drying machine is mainly used for drying fertilizer with certain humidity and particle size in the compound fertilizer and organic fertilizer production. Fertilizer after drying have high temperature and shall be cooled to prevent caking of the fertilizer. Rotary drum cooling machine is used to cool fertilizer with certain temperature and particle size in compound fertilizer production line and organic fertilizer production line. The cooler is used combining with the rotary dryer, which can greatly increase the cooling rate, reduce labor intensity, increase capacity, and further remove the moisture and reduce the temperature of fertilizer.

4) Fertilizer Screening Process

In fertilizer production, the fertilizer granular shall be screened before packaging to ensure the uniformity of the finished product. Rotary drum screening machine is a common equipment used in the fertilizer industry for compound fertilizer production and organic fertilizer production. Rotary screen is mainly used in the fertilizer production line to separate finished product and returning materials. The trommel can also be used for classifying the finished product.

5) Fertilizer Packing

Materials are fed by gravity-type feeder, then enter into weighing system uniformly through gravity-type feeder from stock bin or production line. The gravity-type feeder starts to run after turning on packing machine. Then material will be filled into weighing hopper, through weighing hopper filled into bag. When weight reaches the preset value, the gravity-type feeder will stop running. Operators takes filled bag away, or put it on belt conveyor to sewing machine. The packing process finishes.

Post time: Sep-28-2020