What’s water soluble fertilizer?

Water-soluble fertilizer is a kind of quick action fertilizer, featured with good water solubility, it can thoroughly dissolve in water without residue, and it can be absorbed and utilized directly by root system and foliage of the plant. The absorption and utilization rate can reach 95%. Therefore, it can meet the nutritional needs of high- yielding crops in rapid growth stage.

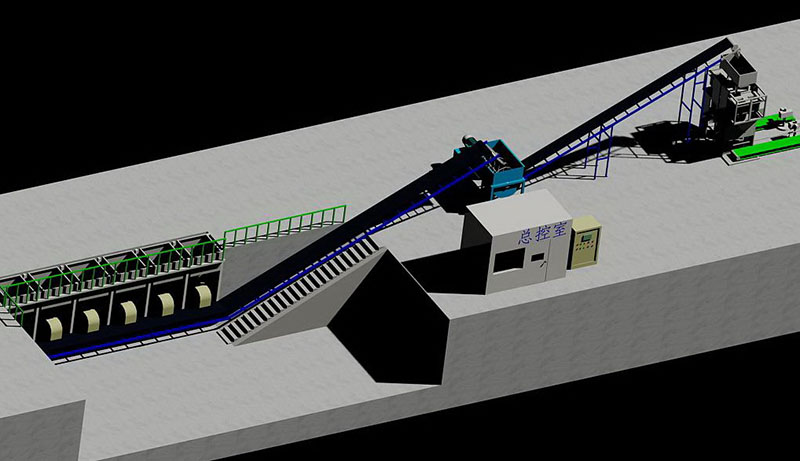

Brief introduction of water soluble fertilizer production line.

Introduction of Water-soluble fertilizer production line

Water-soluble fertilizer production line is a new fertilizer processing equipment. This includes material feeding, batching, mixing and packaging. Mix 1 ~ 5 raw materials according to the fertilizer formula, and then the materials are automatically measured, filled and packed.

Our Static batching water-soluble fertilizer production line series can produce a bag of 10-25kg water-soluble fertilizer products, using the most advanced international control system, internal or external high-precision sensors, it has compact structure, precise batching, even mixing, accurate packaging. Mainly suitable for mass production of water soluble fertilizer manufacturers.

(1) Professional control equipment

Unique feeding system, static batching scale, intermittent mixing, special packing machine for filling water soluble fertilizer, professional conveyor, automatic sewing machine.

(2) Production process

Artificial feeding- Material crusher - Linear screening machine – Bucket elevator – Materials distributor - Spiral conveyor - Computer static batching - Mixing machine - Quantitative packaging machine

(3) Product parameters:

1. Production capacity: 5 tons;

2. Ingredients: 5 kinds;

3. Batching instrument: 1 set;

4. Batching capacity: 5 tons of water-soluble fertilizer per hour;

5. Batching form: static batching;

6. Ingredient precision: ±0.2%;

7. Mixing form: Forced mixer;

8. Mixing capacity: 5 tons intermittent mixing per hour;

9. Transport form: belt or bucket elevator;

10. Packing range: 10-25 kg;

11. Packing capacity: 5 tons per hour;

12. Packaging accuracy: ±0.2%;

13. Environment adaptation: -10℃ ~ +50℃;

Introduction of main equipment of water-soluble fertilizer production line

Storage bin: Storage of incoming materials for processing

The bin is placed above the packing machine and connected directly with the flange of the packing machine. A valve is set below the storage bin for maintenance or timely closing of the feed; The wall of the storage bin is equipped with upper and lower stop spinning level switches for material level monitoring. When the incoming material exceeds the upper stop spinning level switch, the screw feeding machine is controlled to stop feeding. When it is less than the lower stop spinning level switch, the packaging machine will stop working automatically and the state light will flash automatically.

Weighing scale feeding system

This series of electronic scale feeding system, adopts frequency conversion control, there are large, small and instantaneous stop feeding mode, big feeding control packaging speed, small feeding control packaging accuracy. In the case of 25kg packaging, 5% small feeding is adopted when the large feeding reaches 95%. Therefore, this feeding method can not only guarantee the packaging speed but also guarantee the packaging precision.

Measuring system

The feeding system is directly fed into the packaging bag through the storage bin. It is well designed, with small drop difference and good sealing. The bin body is suspended and fixed on the sensor (sensor performance: output sensitivity: 2MV/V accuracy level :0.02 repeatability :0.02%; Temperature compensation range :-10 ~ 60℃; Operating temperature range -20 ~ +65℃; Allowed overload :150%), so that it has no direct contact with the outside so as to achieve higher accuracy.

Clamping bag device

Adopt anti-slip and wear-resisting material, it can customize the width of the entrapment according to the bag of different materials, and the discharging door will automatically open after the next bag is covered, and the feeding will start again; It adopts a closed bag clamping structure and driven by the cylinder, it is easy to operate and simple to maintenance.

Conveyor

Adjustable height, adjustable speed, can turn or reverse, both sides of the belt with guard plate, can make the bag does not deviate and collapse; The standard length is 3m, and the bags are transported to the sewing machine for sewing.

Sewing machine

With automatic sewing function.

Maximum speed: 1400 RPM;

Maximum sewing thickness :8mm,

Stitch adjustment range :6.5 ~ 11mm;

Sewing thread stitch type: double thread chain;

Sewing specifications :21s/5; 20/3 Polyester line;

Lifting height of presser foot :11-16mm;

Machine needle model :80800×250#;

Power: 370 W;

Because the packaging bag height is uncertain, a screw lifting mechanism is set on the column, so that it can be used for bags of different heights; The column is provided with a coil seat for placing the coil;

Control system

Adopting the batching instrument control system, the system has high stability and better corrosion resistance (sealing); Automatic drop correction function; Automatic zero tracking function; Measuring and automatic alarm function; It can be operated manually or automatically. The two modes can be switched at any time.

Workflow:

Turn on the power switch and check whether the power indicator is on. If not, check whether the power is connected well.

Whether each parts work normally under manual state;

Set the formula (the formula can be made according to the operation manual).

Turn on automatic.

One person will put the bag into the automatic entrapment opening, and the bag will start to fill automatically. After the filling, the bag will relax automatically.

The falling bags will be transported to the sewing machine for sewing by the conveyor.

The whole packing process is finished.

Advantages of water-soluble fertilizer production line:

1. The batching system adopts advanced static batching control core components;

2. Due to the poor fluidity of water-soluble fertilizer raw materials, a unique feeding system is adopted to ensure the smooth feeding process of raw materials without blocking.

3. Static batching method is adopted in the batching scale to ensure accurate batching and the batching amount is applicable within 8 tons per hour;

4, Using bucket elevator for feeding (advantages: corrosion resistance, long life, good sealing effect, low failure rate; Small floor space; Design according to customer's site conditions and requirements);

5. The packaging scale control instrument can be accurate to 0.2%.

6. Due to the corrosivity of water soluble fertilizer, the contact parts of this production line are all made of national standard stainless steel with thick, strong and durable plates.

Common problems of water soluble fertilizer and preventive measures

Moisture absorption and agglomerating

The phenomenon of moisture absorption and agglomerating occurs after the finished product is stored for a period of time.

Reason: it is related to the hygroscopicity of raw materials, water content of materials, relative humidity of production environment, and water absorption of packaging materials.

Solution: Pay attention to the storage of raw materials, timely detection of new raw materials, can use hydrated magnesium sulfate agglomerating agent.

2. Packaging flatulence

After the product is placed for a period of time in summer, gas is generated in the packaging bag, causing the packaging to bulge or burst.

Reason: It's usually because the product contains urea, and the gas component is mainly carbon dioxide.

Solution: use aerated packaging materials, pay attention to the storage temperature of the finished products.

3. Corrosion of packaging materials

Reason: Some formulas tend to corrode packaging materials.

Solution: Pay attention to the choice of packaging materials, the selection of packaging materials need to consider the raw materials and formula.

Post time: Sep-27-2020