Introduction of Compound Fertilizer Production Line

Compound Fertilizer is the fertilizer which contains two or three nutrients of N, P; K. Compound fertilizer is available in powder or granular form. It is usually used as topdressing and can also be used as base manure and seed manure. Compound fertilizer contains high effective components, so it is easily soluble in water, decomposes quickly, and is easily absorbed by the root system, so it is called "quick-acting fertilizer". Its function is to meet the comprehensive demand and balance different nutrients required by crops under different conditions.

This fertilizer production line is mainly used to granulate compound fertilizer granules using materials of NPK, GSSP, SSP, granulated potassium sulphate, sulphuric acid, ammonium nitrate, and others. The compound fertilizer equipment has advantages of running stable, low malfunction rate, small maintenance and low price.

The whole production line is equipped with advanced and efficient equipment, which can achieve an annual output of 50,000 tons of compound fertilizer. According to the actual production capacity requirements, we plan and design the compound fertilizer production lines with different annual capacity of 10,000 ~ 300,000 tons. The whole set of equipment is compact, reasonable, scientific, stable operation, energy-saving, low maintenance cost, easy to operate, is the best choice for compound fertilizer manufacturers.

Medium compound fertilizer production line process

The process of compound fertilizer production line can be generally divided into: raw material batching, mixing, crushing, granulating, primary screening, granule drying and cooling, secondary screening, granule coating and quantitative packaging.

1. Raw materials batching: according to market demand and local soil determination results, raw materials such as urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, general calcium) and potassium chloride (potassium sulphate) shall be allocated in a certain proportion. The additives and trace elements are weighed by the belt scale and proportioned to a certain proportion. According to the formula ratio, all the raw materials are evenly mixed by the mixer. This process is called premix. It ensures accurate formulation and enables efficient and continuous batching.

2. Mixing: Fully mix the prepared raw materials and stir them evenly, which lays a foundation for efficient and high-quality granular fertilizer. Horizontal mixer or disc mixer can be used for even mixing.

3. Crushing: To crush the caking in the materials is necessary for subsequent granulation processing. Chain crusher is mainly used.

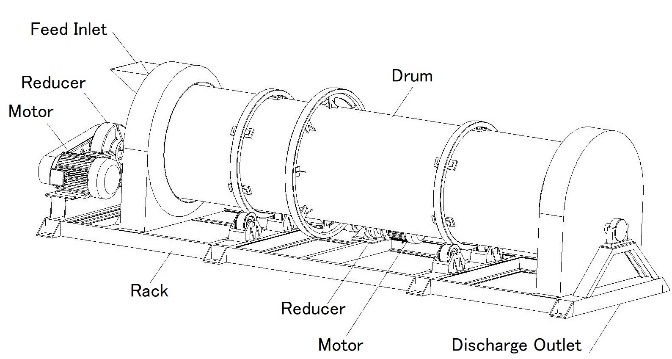

4. Granulating: The evenly stirred and crushed materials are transported to the granulator through the belt conveyor for granulating, which is the core part of the whole production line. The choice of granulator is quite important, we have disc granulator, rotary drum granulator, roller extrusion granulator or compound fertilizer granulator for choice.

5. Primary screening: Take preliminary screening for granules, and return unqualified ones to the crushing for reprocessing. Generally, the rotary screening machine is used.

6. Drying: The qualified granules after primary screening are transported by the belt conveyor to the rotary dryer for drying to reduce the moisture content of the finished granules. After drying, the moisture content of granules will decreased from 20%-30% to 2%-5%.

7. Granules cooling: After drying, the granules shall be sent to the cooler for cooling, which is connected with the dryer by the belt conveyor. The cooling can remove dust, improve the cooling efficiency and heat utilization ratio, and further remove the moisture in the fertilizer.

8. Secondary screening: After cooling, all unqualified granules are screened out through the rotary screening machine and transported by the belt conveyor to the mixer and then mixed with the other raw materials for reprocessing. The finished products will be transported to the compound fertilizer coating machine.

9. Coating: It is mainly used to coat the surface of quasi-granules with a uniform protective film to effectively extend the preservation period and make granules smoother. After coating, here come to the last process - packaging.

10. Packaging system: Automatic quantitative packaging machine is adopted in this process. The machine is composed of automatic weighing and packing machine, conveying system, sealing machine and so on. Hopper can also be configured according to customer requirements. Quantitative packaging of bulk materials such as organic fertilizer and compound fertilizer has been widely used in used in different industries and fields.

Technology and Features of compound fertilizer production line:

Rotary drum granulator is mainly used in the production of high-concentration compound fertilizer technology, disc non-steam granulator can be used in the production of high, medium and low concentration of compound fertilizer technology, combined with the anti-caking technology, high nitrogen compound fertilizer producing technology and so on. Our compound fertilizer production line has the following characteristics:

1. Wide applicability of raw materials: compound fertilizers can be produced according to different formulations and proportions, and it is also suitable for the production of organic and inorganic compound fertilizers.

2. High pellet-forming rate and survival rate of biological bacteria: the new technology can make the pellet-forming rate reach 90% ~ 95%, and the low-temperature and high-air drying technology can make the survival rate of microbial bacteria reach 90%. The finished product is good in appearance and uniform in size, 90% of which are granules with a size of 2 ~ 4mm.

3. Flexible process flow: The process flow of compound fertilizer production line can be adjusted according to the actual raw materials, formula and site, and customized process flow can also be designed according to the actual needs.

4. Stable nutrient ratio of finished products: through automatic metering of ingredients, accurate metering of all kinds of solid, liquid and other raw materials, almost maintained the stability and effectiveness of all nutrients in the whole process.

Compound Fertilizer Production Line Applications

1.Sulfur coated urea production process.

2.Different kind of organic and inorganic fertilizer process.

3.Acid compound fertilizer granulation process.

4.Powdery industrial waste inorganic fertilizer process.

5.Large particle urea production process.

6.Seedling Substrate fertilizer production process.

Post time: Sep-27-2020