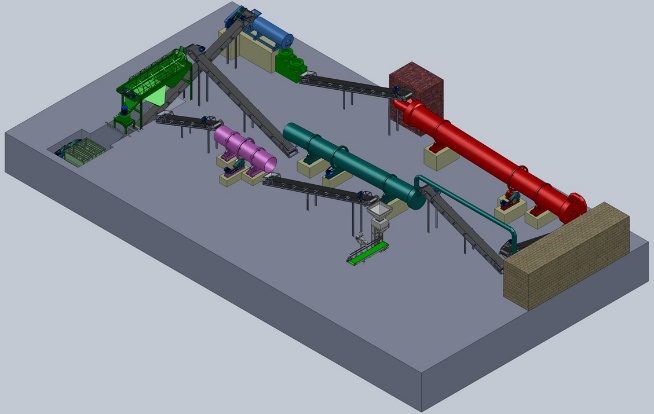

Introduction of Organic Fertilizer Production Line

This fertilizer production line manufactured by us can produce 30,000 tons of organic fertilizer granules per year, with tons of various organic wastes being turned into organic fertilizer. The bio-organic fertilizer plant not only turn wastes (such as chicken manure, kitchen waste etc.) into treasure, but also reduce environment pollution. The granular shape can be cylindrical or spherical, convenient for transportation and application. The equipment is optional according to your actual requirement.

Rich Raw Material Resources

The organic fertilizer plant has rich material resources. The equipment may differ for different materials.

1.Animal waste, animal mature, such as chicken, pig, duck, cattle, sheep, horse, rabbit, animal residue, such as fish meal, bone meal, feather, fur, silkworm excrement, biogas residue, etc.

2.Agriculture waste. Crop straw, vine, soybean meal, rapeseed meal, cottonseed meal, caster bean meal, tee seed meal, yeast powder, mushroom residue, etc.

3.Industrial waste. Vinasse, vinegar residue, manioc waste, filter mud, herb residue, furfural residue, etc.

4.Municipal sludge. River sludge, pound sludge, ditch sludge, sea mud, lake mud, sewage sludge, humic acid, turf, lignite, danty, fly, ash, etc.

5.Household garbage. Kitchen waste, etc.

6.Extracted or concentrated organics, seaweed extract, fish extract, etc.

Main equipment of 30,000 Ton Organic Fertilizer Granulator Line.

1.Compost turner

1.Compost turner

Fermentation process decomposes the organic waste and turns them into organic fertilizer. We provide different types of compost turners: self-propelled organic fertilizer compost turning machine, double-screw compost turner, hydraulic compost turner, groove type turner, and groove type hydraulic compost turner, all of which have gained great popularity in the international market. You can choose according to actual materials, sites and finished product requirements.

2.Semi-wet Material Crusher

The fermented materials enter into the semi-wet material crusher, which can crush fermented materials with moisture content within 30%. The size can reach 20-30 mesh, meeting the requirement of granulation.

3.Horizontal mixer

After crushing, auxiliary materials are added into the materials according to the formula and mixed in the mixer. We provide single-shaft and double-shaft horizontal mixer for you to mix the materials evenly.

4.New Type Organic Fertilizer Dedicated Granulator

This machine can help reduce the energy that is wasted in the drying process, because the granules can be immediately screened after the granulation process. The purity of organic fertilizer granules can reach as high as 100%, which makes the pure organic fertilizer production come true and meet the need of customers directly. The quality of the fertilizer granules can be ensured at the same time. So this machine is featured with low energy consumption, low production expenses and high production quality and is considered as the best choice for pure organic fertilizer production.

5.Ball-shaping Machine

This machine can shape the different fertilizer granules which are produced by extruding granulator or disc granulator, and these granules will have the uniform size, precise roundness, smooth surface and large particle strength after the ball-shaping, the fertilizer’s ball-forming rate will up to 98%. It has the advantages of no return material, high ball forming rate, high strength and good appearance.

6.Rotary Drum Dryer and Cooler

The granules coming from the granulator have high moisture content and should be dried to meet the standard. Rotary drum dryer adopts hot air to dry the granules.

Dried granules has very high temperature and should be cooled to prevent caking. Rotary drum cooling machine is used in combination with the dryer to further remove the moisture and lower the temperature.

7.Rotary Screening Machine

Cooled fertilizer granules enter into the rotary screening machine. Unqualified granules are returned to the crusher. Qualified granules are sent to the coating machine.

8.Rotary Coating Machine

Rotary coating machine is an equipment for coating pellets with powder or liquid. The. equipment is specially designed according to the process requirements on the internal structure. The coating process can effectively prevent the caking of fertilizer and achieve the effect of slowing release.

9.Granules Packing Machine

Granules packing machine is used for the quantitative packing of fertilizer granules. It consists of automatic weighing and packing machine, conveyor, sealing machine and feeder. High weighing accuracy, convenient operation. Packed fertilizer will be stored for sale.

Features of Organic Fertilizer Production Line

1.Adopt semi-wet materials crusher, have strong adaptability to the moisture content.

2.Granules polishing machine makes spherical granules with uniform size, smooth surface and high strength. Suitable for connecting with various granulators.

3.Belt conveyor is and other supporting equipment are used to connect the whole line.

4.Compact structure ,stable performance, easy operation and maintenance.

5.The equipment is optional according to your actual requirements.

Technical Data of 30,000 T/Y Organic Fertilizer Production Line

Production line – Fermentation part

| No. | Name | Model | Power(KW) | Quantity | Amount (ten thousand yuan) |

Picture | Description |

| 1 | Forklift feeder | CWL-2040 | 7 | 1 | 2.31 |

|

1. Adopt separate structure of load-bearing and traction to improve the impact load bearing capacity of the feeder.2. Forklift feeder is equipped with anti-smash net to reduce the impact of large amount of feeding.3. The forklift feeder is equipped with a stirring shaft and a vibrating motor to prevent blockage of high-wet materials.

4. The conveying part of the lower belt is adjustable speed belt, which can accurately control the feeding amount. 5. Feeding bin feeding port size: 2m*3m (position size of motor and reducer is not included) |

| 2 | Crawler compost turning machine | FDJ-2400 | 38~55 Diesel engine | 1 | 12.1 |  |

1. This product adopts the mechanical intelligence technology to realize the infinitely variable speed of the machine’s walking and turning, which can precisely set the running speed of the wheel and turning shaft according to the nature of materials to obtain the best output and quality.2. The power is 81 horsepower vertical water-cooled diesel engine, with sufficient power, high efficiency and low fuel consumption.3. This machine adopts the professional technology of turning around in place, 360° sharp turning steering device, with flexible steering, small floor space and convenient site operation.

4. All electric button switch control, flexible and simple. 5. In order to adapt to the operation under the environment of severe corrosion, the frame and guard plate are all thickened with national standard materials in our manufacturing process . 6. Hydraulic mode can be adopted to adjust the distance between the stacking shaft and the ground. Prevent the turning shaft knife from touching the ground. (According to customer requirements) 7. Equipped with cab. 8. Air conditioning can be installed according to customer requirements.

|

| 3 | Screening machine | GS-1240 | 3*2 | 2 | 4.16 |  |

1. The screen is made of stainless steel to prevent corrosion.2. According to the customer’s requirements, the anti-stick net device can be added.3. The function of this screening machine is to screen the dried particles, the finished products enter the packaging process, and the waste products return to crush again.

|

| 4 | Vertical Crusher | LP-800 | 30 | 1 | 2.3 |

|

1. The crusher adopts the compound structure of chain blade, which can crush the material with water content below 40% to prepare for granulation.2. The chain is made of high manganese alloy, and the blade is made of spring steel, which has the advantage of durable wear resistance.3. The rotor is dynamically balanced and can work stably without foundation.

4. Dust removal treatment is carried out at the discharge port to prevent the overflow of dust. 5. The crusher has high crushing efficiency and is not easy to be stuck and blocked. It is equipped with an observation window. 6. The diameter of the barrel is 1000mm, and the wall thickness of the barrel is 10mm |

Production line – Granulating part

| No. | Name | Model | Power(KW) | Quantity | Amount (ten thousand yuan) |

Picture | Description |

| 6 | Double -helix horizontal Crusher | HC-80 | 11 | 2 | 4.2 |  |

1. Double helix structure is adopted in the mixing blade, which ensures even mixing and high efficiency.2. The mixing blade is made of high-strength and wear-resisting material, which is more durable.

3. The minimum clearance between the rotor and the shell can be adjusted to close to zero, effectively reducing the material residue. 4. Body thickness: 6mm |

| 7 | New organic fertilizer granulator | JZLG-1000 | 75 | 1 | 8.19 |  |

1. The granulator is a patented product of our company.2. The contact part between granulator and material is made of 304 stainless steel.

3. The tool head of inside mixing gear adopts carbide tool head. 4. Production capacity: 2.5-3.5t/h 5. External dimension: 4700*2350*1600mm |

| 8 | Rotary dryer | HG-15150 | 15 | 1 | 12.05 |  |

1. The cylinder of the dryer is a 14mm thick integrated spiral tube, which has the advantages of high concentricity, strong rigidity and stable operation. The lifting plate thickness is 8mm.2. Gear ring, roll belt, idler and bracket are all steel castings.

3. The induced draft fan has been corrected by static and dynamic balance, so it runs smoothly and has high strength. 4. Adopt downstream drying mode. The airflow of material and heat source enters into the drying equipment from the same side. 5. Proper operation parameters balance the heat source, material and wind direction, thus greatly improving the thermal efficiency and reducing drying energy consumption by 30-50% or more. |

| 9 | Rotary cooler | HG-12120 | 7.5 | 1 | 11.05 |  |

1. The cooling machine barrel is a 14mm thick integrated spiral tube with the advantages of high concentricity, strong rigidity and stable operation. The lifting plate thickness is 6mm.2. Gear ring, roller and bracket are cast steel.

3. The induced draft fan has been corrected by static and dynamic balance, so it runs smoothly and has high strength. 4. Proper operation parameters to balance the “material and wind”, so as to greatly improve the cooling efficiency and make the cooling energy consumption reducing by 20-50% or more. |

| 10 | Coating machine | BM-10400 | 5.5 | 1 | 4.29 |  |

1. The cylinder body of the machine is lined with special rubber sheet or acid-resistant stainless steel liner.2. The coating machine is used together with dry powder coating agent spray system.

3. The transmission system and roller bracket of the coating machine are all steel castings. |

| 11 | Quantitative packing machine | QP-301127 | 1.1 | 1 | 4.2 |  |

1. The contact part with the material is made of 304 stainless steel.2. Specially designed feeding, measuring, bagging and unloading at the same time. Save one third of the operation time.

3. Imported sensors, imported pneumatic actuators, reliable work, simple maintenance. The measuring accuracy is plus or minus two parts per thousand. 4. Wide range of quantitative, high precision, with table lifting conveyor seam machine, a multi-purpose machine, high efficiency. 5. Bucket packing scale (including packing machine, sealing machine and connected belt machine) |

Production line – Supporting part

| No. | Name | Name | Power(KW) | Quantity | Amount (ten thousand yuan) |

Picture | Description |

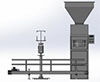

| 12 | Storage bin | 1 | 0.455 |  |

The storage bins are widely used in various fertilizer production lines, generally gathering materials to the belt conveyor and delivered to the next deep processing. The bin is cheap and durable. | ||

| 13 | Chain crusher for returned materials | LP-600 | 15 | 1 | 0.105 |  |

1. The outer wall of the crusher is made of 8mm thick manganese steel plate.2. The crusher chain is made of high strength alloy.

3. The crushing material is uniform, not easy to stick to the wall, and easy to clean. 4. The inner wall can be made of rubber or stainless steel (according to customer needs) to achieve smooth surface and easy to clean. 5. Quick-opening access doors are arranged on both sides of the body. The main body and transmission device are installed on the same base which made of steel, and the shock absorber is installed below the base and connected with the foundation. 6. Cylinder size: 0.6m |

| 14 | 1.2*2M storage bin | - | 1 | 0.95 | The storage bins are widely used in various fertilizer production lines, generally gathering materials to the belt conveyor and delivered to the next deep processing. The bin is cheap and durable. This size is 1.2*2M. | ||

| 15 | Quantitative packing machine | QP-301127 | 1.1 | 1 | 4.2 |  |

1. The contact part with the material is made of 304 stainless steel.2. Specially designed feeding, measuring, bagging and unloading at the same time. Save one third of the operation time.

3. Imported sensors, imported pneumatic actuators, reliable work, simple maintenance. The measuring accuracy is plus or minus two parts per thousand. 4. Wide range of quantitative, high precision, with table lifting conveyor seam machine, a multi-purpose machine, high efficiency. 5. Bucket packing scale (including packing machine, sealing machine and connected belt machine) |

| 16 | Cyclone dust collector | SXXC-1200 | - | 2 | 5.4 |  |

1. Cyclone dust collector is simple in structure, easy to manufacture, install, maintain and manage, and low in equipment investment and operation cost.2. The cyclone dust collector is composed of inlet pipe, exhaust pipe, cylinder body, cone body and ash bucket.

3. Each part of the cyclone dust collector has a certain size ratio. The diameter of the dust collector, the size of the air inlet and the diameter of the exhaust pipe are accurately calculated by the engineer to ensure the best dust removal effect. |

| 17 | 6C induced draft fan | SXYF-12C | 15 | 1 | 0.8 |  |

1.The induced draft fan is calibrated by static and dynamic balance, so it runs smoothly and has high strength. The induced draft fan and connecting pipe are matched with the dryer.2. The impeller is composed of 10 recumbent wing blades, curved front plate and flat rear plate. Its material is made of copper plate or cast aluminum alloy, and by dynamic and static balance calibration, good air performance, high efficiency, smooth operation.

3. The air inlet is made into a whole and loaded into the side of the fan. The section parallel to the axial direction is a curved shape, which enables the gas to enter the impeller smoothly and with small air loss. |

| 18 | Water curtain dust remover | SXSC-1500 | - | 1 | 1.95 | 1. The water curtain dust remover pumps water to the top of the dust remover through high pressure water pump. The flue gas and dust generated in the production process are extracted by a uniquely designed three-channel spray device.2. The waste water can be directly introduced into the fermentation tank to eliminate secondary pollution, and the amount of waste water is very small. | |

| 19 | 8C induced draft fan | SXYF-8C | 22 | 1 | 1.8 |  |

1.The induced draft fan is calibrated by static and dynamic balance, so it runs smoothly and has high strength. The induced draft fan and connecting pipe are matched with the dryer.2. The impeller is composed of 10 recumbent wing blades, curved front plate and flat rear plate. Its material is made of copper plate or cast aluminum alloy, and by dynamic and static balance calibration, good air performance, high efficiency, smooth operation.

3. The air inlet is made into a whole and loaded into the side of the fan. The section parallel to the axial direction is a curved shape, which enables the gas to enter the impeller smoothly and with small air loss. |

| 20 | Belt conveyor | B500 | 57 | 126(850/m) | 10.71 |

|

1. The frame adopts 10mm channel steel.2. All rollers are national standard heavy-duty rollers.

3. Transmission gears and bearing seats are thickened steel castings. |

| 21 | Integrated electric control cabinet | 3.3 | Electrical components are ZhengTai brand | ||||

| 22 | Pipe for dryer and cooler | 2.8 | 1. Connection pipe of dryer and cooler. | ||||

| Total | 97.32(EXW) | ||||||

| Gas source (air pump for packing scale), cable, wire, steel accessories purchased by customers. | |||||||

Note: This procedure is for reference only and depends on customer requirements, site conditions and raw materials.

Post time: Sep-27-2020