First, let's have a look at the raw materials used in the production of compound fertilizer:

1) Nitrogen fertilizer: ammonium chloride, ammonium sulfate, ammonium sulfide, urea, calcium nitrate, etc.

2) Potassium fertilizer: potassium sulfate, grass ash, etc.

3) Phosphate fertilizer: superphosphate, heavy superphosphate, calcium magnesium phosphate fertilizer, phosphate powder, etc.

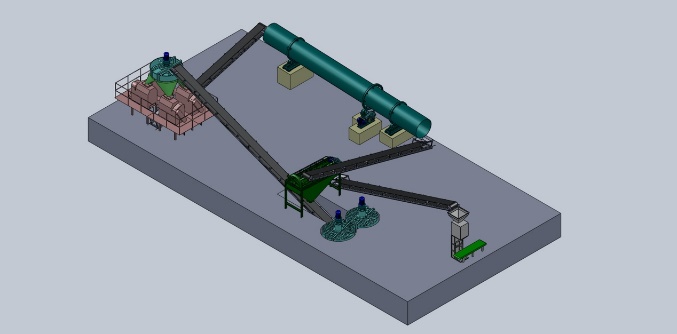

20,000 Tons/Year Compound Fertilizer Granulation Production Line Introductions:

This 20,000 t/y compound fertilizer production line is a combination of a series of advanced equipment. It is featured with low production expenses and high production efficiency. This production line can be used for granulating all kinds of compound raw materials. And the final fertilizer particles can be made with different concentrations according to the actual needs, which can effectively supplement the necessary nutrients for crops and resolve the conflicts between the needs of crops and the supply of the soil.

Generally speaking, a compound fertilizer production line usually consists of these following parts: the mixing process, granulating process, drying process, cooling process, screening process, coating process and packaging process.

20,000 t/y compound fertilizer Granulation Production Line Main Components:

1.Dynamic batching machine

The batching machine is equipped with three or more bins, which can be added or reduced according to customer requirements. The exit of each bin is equipped with pneumatic electronic doors, and the bottom of the bin is weighting hopper, and the bottom of the hopper is connected with belt conveying device. The hopper and belt conveyor are suspended at one end of the driving lever, and the other end of the lever is connected with the tension sensor, and the sensor and pneumatic control part are connected with the computer. The machine adopts the electronic weighing machine, which is automatically controlled by the batching controller to complete the weighing ratio of each material in turn. It has the advantages of simple structure, high precision of batching and simple operation.

2.Vertical Chain Crusher:

Assemble different compound materials according to a certain proportion, and then put them into the Vertical Chain Crusher. The raw materials will be crushed into small particles so that they can meet the needs of granulating process.

3.Disc Mixer:

After the raw materials are crushed, they will be sent to the Disc Mixer, in which the raw materials will be uniformly blended. The lining of the pan is made of polypropylene or stainless steel sheet, so the corrosive materials with high viscosity are not easy to stick,which helps improve the working efficiency as well as the production quality. Then the mixed materials will be sent in to the Rotary Drum Granulator.

4.Rollers extrusion granulation:

Using dry extrusion technology, no drying process is required. It is mainly by external pressure, the material forced through the clearance between two reverse rotation rollers, and compressed into pieces. The actual density of the material can be increased by 1.5-3 times to reach a certain strength standard. The extrusion pressure can be adjusted by hydraulic system. This machine has the advantages of large working flexibility and wide using range. It is not only scientific and reasonable in structure, but also with less investment, quick effect and good economic benefit.

5.Rotary Drum Screening machine:

After enter into the rotary drum screening machine, the qualified particles will be sent into the coating machine, while the unqualified particles will be selected and then sent into the Vertical Chain Crusher to be granulated again. This machine adopts assembly screen, which is convenient for maintenance and replacement. The structure is simple, operation is convenient, and running is stable. It is an indispensable equipment in fertilizer production line.

6.Rotary Fertilizer Coating Machine:

The qualified particles will be coated by the rotary fertilizer coating machine, which will beauty the particles and strengthen their hardness at the same time. The rotary fertilizer coating machine adopted special liquid material spraying technology and solid powder coating technology to prevent the caking of the fertilizer particles effectively.

7.Fertilizer Packaging Machine:

After the particles are coated, they will be packaged by the packaging machine. The packaging machine has a high degree of automation, which integrates weighing, stitching, packaging and conveying, realizing fast quantitative packaging to make the packaging process more efficient and accurate.

8.Belt Conveyors:

Conveyors plays an indispensable role in the production process, because it connects different parts of the whole production line. In this compound fertilizer production line, we choose to provide you with the belt conveyors. Compared with other kinds of conveyors, the belt conveyor has a large coverage, which will make your production process more efficient and economic.

Advantages of 20,000 Tons/Year Compound Fertilizer Production Line:

1.This compound fertilizer production line is a featured with low consumption, high production capacity and good economic benefit.

2.The production line adopts the dry granulation technology, which skips the drying and cooling process and greatly reduces the cost.

3.Designed with the compact and reasonable structures, the compound fertilizer production line will have a great working capacity, which can be more suitable to the demands of the compound fertilizer production at present.

4.During the producing process, less energy is consumed and no three waste are created. This compound fertilizer production line has a steady performance and reliable quality which prolongs a longer service life.

5.This compound fertilizer production line can be applied to producing all kinds of compound raw materials. And the granulation rate is high enough.

6.This compound fertilizer production line can be used to produce compound fertilizer with different concentrations, which can meet the needs of different customers.

Post time: Sep-27-2020