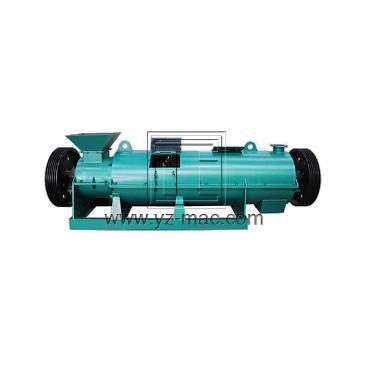

New type organic fertilizer granulator

The new type organic fertilizer granulator in the field of fertilizer production. This innovative machine combines advanced technology and design to transform organic materials into high-quality granules, offering numerous advantages over traditional fertilizer production methods.

Key Features of the New Type Organic Fertilizer Granulator:

High Granulation Efficiency: The new type organic fertilizer granulator employs a unique granulation mechanism that ensures high efficiency in converting organic materials into uniform granules. It achieves a high granulation rate, minimizing waste and maximizing the yield of quality organic fertilizer.

Versatile Material Compatibility: This granulator can handle a wide range of organic materials, including livestock manure, crop residues, food waste, green waste, and sludge. It offers flexibility in material selection, allowing farmers and fertilizer producers to utilize various organic resources.

Uniform Granule Size: The new type organic fertilizer granulator produces uniform-sized granules, which are essential for consistent nutrient distribution and effective fertilization. The granules have a smooth surface, facilitating easy handling, storage, and application.

Controlled Release of Nutrients: The granules produced by the new type organic fertilizer granulator have controlled-release properties, ensuring a gradual and sustained release of nutrients to the plants. This promotes optimal nutrient uptake, reduces nutrient leaching, and enhances crop growth and productivity.

Working Principle of the New Type Organic Fertilizer Granulator:

The new type organic fertilizer granulator utilizes the principle of wet granulation. Organic materials are first dried to an appropriate moisture content and then fed into the granulation chamber. Inside the chamber, a rotating drum with mixing blades evenly distributes the materials and adds a binder solution if necessary. As the drum rotates, the materials adhere together, forming granules. The granules are then dried and cooled before being screened to obtain the desired size range.

Applications of the New Type Organic Fertilizer Granulator:

Agriculture and Crop Production: The granules produced by the new type organic fertilizer granulator are an excellent source of nutrients for agricultural crops. They improve soil fertility, enhance nutrient availability, and promote healthy plant growth. The controlled-release properties of the granules ensure a sustained nutrient supply, reducing the frequency of fertilizer application.

Organic Farming: Organic farmers can benefit from the new type organic fertilizer granulator to produce high-quality organic fertilizers. The granules are derived from organic materials, aligning with organic farming practices. They provide a balanced nutrient composition and contribute to the improvement of soil health and long-term sustainability.

Horticulture and Gardening: The uniform granules produced by the new type organic fertilizer granulator are well-suited for horticultural applications. They can be used in greenhouse production, nurseries, and home gardens to enrich the soil, promote healthy plant growth, and enhance the quality and yield of fruits, vegetables, flowers, and ornamental plants.

Commercial Fertilizer Production: The new type organic fertilizer granulator is widely utilized in commercial fertilizer production facilities. It offers an efficient and cost-effective solution for converting organic materials into marketable organic fertilizers. The high granulation efficiency and versatility make it a valuable asset in large-scale fertilizer production operations.

The new type organic fertilizer granulator represents a significant advancement in fertilizer production technology. Its high granulation efficiency, versatility in material compatibility, production of uniform granules, and controlled-release properties set it apart from traditional fertilizer production methods. With applications in agriculture, organic farming, horticulture, and commercial fertilizer production, the new type organic fertilizer granulator plays a pivotal role in promoting sustainable agriculture practices, enhancing soil fertility, and contributing to global food security.