Machine for fertilizer

A fertilizer making machine is a valuable tool in the process of nutrient recycling and sustainable agriculture. It enables the transformation of organic waste materials into high-quality fertilizers that can enrich soil fertility and support healthy plant growth.

The Importance of Fertilizer Making Machines:

Fertilizer making machines play a crucial role in sustainable agriculture by addressing two key challenges: the efficient management of organic waste materials and the need for nutrient-rich fertilizers. By converting organic waste into fertilizers, these machines contribute to the circular economy and reduce reliance on synthetic fertilizers, minimizing environmental impact.

Types of Fertilizer Making Machines:

Compost Turner:

A compost turner is a machine designed to mix and aerate organic waste materials, facilitating the composting process. It helps create an ideal environment for microbial activity, promoting decomposition and the conversion of organic matter into nutrient-rich compost. Compost turners are available in various sizes and configurations, suitable for both small-scale and large-scale composting operations.

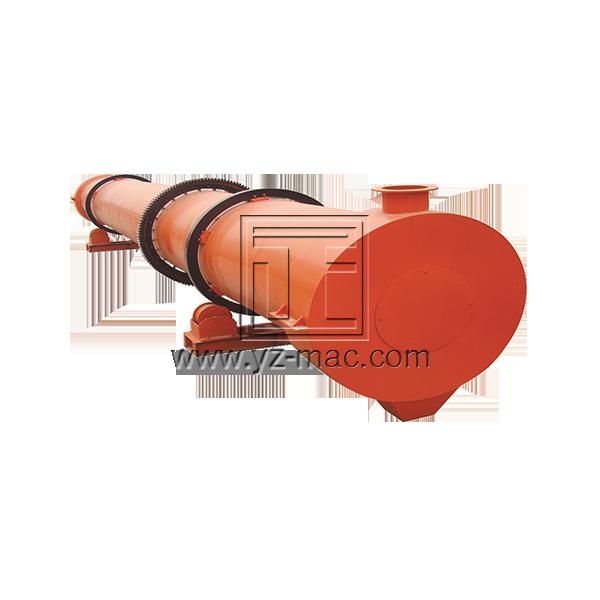

Organic Fertilizer Granulator:

An organic fertilizer granulator is used to shape and compact organic materials into granules. This machine helps improve the handling and storage of organic fertilizers, ensuring even distribution and controlled release of nutrients. Organic fertilizer granulators can be rotary drum granulators, disc granulators, or other types, each offering specific advantages depending on the desired fertilizer characteristics.

Fertilizer Mixer:

A fertilizer mixer is employed to blend different fertilizer components, ensuring a balanced nutrient content and uniformity of the final product. These machines help achieve optimal nutrient ratios and improve the effectiveness of fertilizers. Fertilizer mixers can range from simple paddle mixers to complex vertical or horizontal mixers, accommodating various production capacities.

Fertilizer Crusher:

A fertilizer crusher is used to crush larger organic materials into smaller particles, facilitating further processing and granulation. By reducing the particle size, a fertilizer crusher enhances the efficiency of subsequent steps in the fertilizer production process. Crushers can be in the form of hammer mills, cage mills, or other configurations, depending on the specific application requirements.

Applications of Fertilizer Making Machines:

Agriculture and Horticulture:

Fertilizer making machines find extensive applications in agriculture and horticulture. They enable farmers and gardeners to convert organic waste, such as crop residues, animal manure, and food scraps, into nutrient-rich fertilizers. These fertilizers improve soil fertility, enhance nutrient availability, and promote healthy plant growth.

Organic Farming:

For organic farmers, fertilizer making machines are essential for producing organic fertilizers that meet organic certification standards. These machines help recycle organic waste materials on the farm, minimizing reliance on synthetic fertilizers and promoting sustainable farming practices.

Commercial Fertilizer Production:

Fertilizer making machines are employed in commercial fertilizer production, allowing for large-scale manufacturing of high-quality fertilizers. They enable efficient processing of organic waste materials sourced from various sectors, including agriculture, food processing, and animal husbandry.

Environmental Waste Management:

Fertilizer making machines contribute to effective waste management by converting organic waste into valuable fertilizers. This reduces the environmental impact of waste disposal and promotes resource conservation through the recycling of nutrients.

Fertilizer making machines play a vital role in the sustainable management of organic waste and the production of high-quality fertilizers. By converting organic waste materials into nutrient-rich fertilizers, these machines support sustainable agriculture, reduce reliance on synthetic fertilizers, and promote nutrient recycling. Compost turners, organic fertilizer granulators, fertilizer mixers, and fertilizer crushers offer various functionalities to facilitate the fertilizer production process. Whether for small-scale or large-scale operations, the applications of fertilizer making machines span agriculture, horticulture, organic farming, commercial production, and environmental waste management.