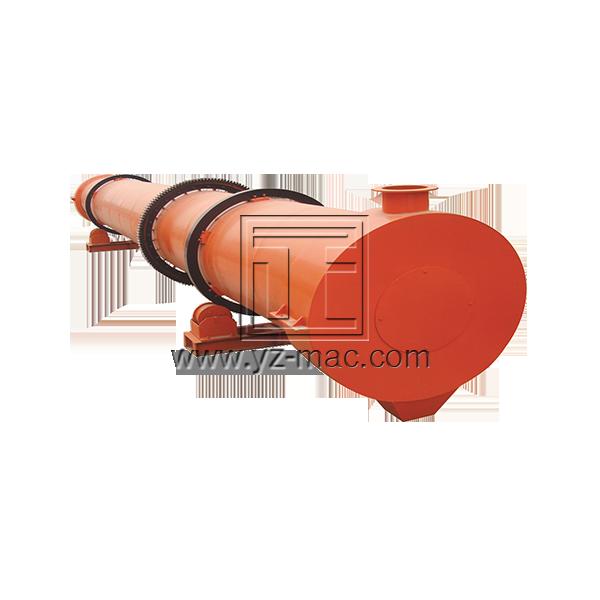

Machine compostage industriel

An industrial composting machine is a specialized equipment designed to handle large volumes of organic waste efficiently. With its advanced features and robust capabilities, this machine streamlines the composting process in industrial settings, enabling effective waste management and sustainable practices.

Benefits of an Industrial Composting Machine:

High Capacity Processing: An industrial composting machine can handle significant volumes of organic waste, making it suitable for industrial-scale operations. It efficiently processes large quantities of organic materials, such as agricultural residues, food waste, yard trimmings, and other biodegradable waste streams.

Rapid Decomposition: Industrial composting machines are designed to optimize the composting process, facilitating rapid decomposition. With advanced mechanisms such as temperature control, aeration systems, and turning features, these machines create ideal conditions for microbial activity, accelerating the breakdown of organic matter and shortening the composting cycle.

Reduced Landfill Waste: By diverting organic waste from landfills, industrial composting machines contribute to waste reduction and promote a circular economy. Composting the organic materials instead of landfilling them reduces greenhouse gas emissions and helps conserve valuable landfill space.

Nutrient-Rich Compost Production: Industrial composting machines produce high-quality compost rich in organic matter and nutrients. This nutrient-dense compost can be used in agriculture, landscaping, horticulture, and soil remediation, enhancing soil fertility, improving crop yields, and promoting sustainable practices.

Key Features of an Industrial Composting Machine:

Large Capacity: Industrial composting machines are designed to handle substantial volumes of organic waste, typically measured in tons or cubic meters. Consider the processing capacity of the machine to ensure it aligns with your waste management requirements.

Efficient Mixing and Aeration: Look for an industrial composting machine with effective mixing and aeration systems. These features promote even distribution of moisture, oxygen, and microorganisms throughout the compost pile, ensuring optimal decomposition and preventing odor issues.

Temperature Control: Industrial composting machines often incorporate temperature control systems to regulate and maintain the ideal temperature range for efficient composting. This helps create the conditions necessary for microbial activity and ensures pathogen and weed seed destruction.

Turning Mechanism: Some industrial composting machines feature a turning mechanism or automated turning system. This feature facilitates regular mixing and turning of the compost pile, promoting homogeneity and aeration, and reducing the need for manual labor.

Odor Management: Industrial composting machines may include odor management systems, such as biofilters or activated carbon filters, to minimize odorous emissions. These systems help maintain a pleasant working environment and prevent potential odor-related concerns.

Applications of Industrial Composting Machines:

Agriculture and Farming: Industrial composting machines play a crucial role in agricultural and farming operations. They process crop residues, livestock manure, and agricultural byproducts, producing nutrient-rich compost for soil improvement, organic fertilization, and sustainable farming practices.

Food and Beverage Industry: Industrial composting machines are utilized in the food and beverage industry to manage organic waste generated during food processing, manufacturing, and distribution. These machines efficiently compost food scraps, expired products, and food waste, minimizing environmental impact and supporting circular economy principles.

Municipal Waste Management: Industrial composting machines are employed in municipal waste management systems to handle organic waste collected from residential, commercial, and institutional sources. They enable the processing of green waste, yard trimmings, food waste, and other organic materials, reducing the overall waste sent to landfills.

Landscaping and Horticulture: Industrial composting machines contribute to the production of high-quality compost used in landscaping projects, horticultural applications, and nurseries. The nutrient-rich compost improves soil health, enhances plant growth, and reduces the reliance on synthetic fertilizers.

An industrial composting machine offers numerous benefits, including high-capacity processing, rapid decomposition, waste reduction, and nutrient-rich compost production.