Machine a composte

A compost machine, also known as a composting machine or composting system, is a specialized equipment designed to simplify the composting process and efficiently transform organic waste into nutrient-rich compost. With various features and capabilities, compost machines offer convenience, speed, and effectiveness in compost production.

Benefits of Compost Machines:

Time and Labor Efficiency: Compost machines automate the composting process, reducing the need for manual turning and monitoring. They save significant time and labor compared to traditional composting methods, allowing for increased productivity and scalability.

Rapid Decomposition: Compost machines provide optimal conditions for microorganisms to break down organic waste rapidly. These machines regulate temperature, moisture, and aeration levels, creating an ideal environment for efficient decomposition. As a result, composting time is significantly reduced, and compost production is accelerated.

Odor and Pest Control: Compost machines are designed to effectively control odors and minimize attraction to pests. They provide enclosed or controlled environments that help contain odorous emissions and prevent unwanted critters from accessing the compost pile.

Space Efficiency: Compost machines are available in various sizes, including compact models suitable for small spaces. They maximize space utilization by efficiently composting organic waste without requiring large outdoor composting areas. This makes them ideal for urban settings or locations with limited space.

Types of Compost Machines:

In-vessel Composters: In-vessel composters consist of enclosed containers or drums that provide controlled environments for composting. These machines offer precise control over factors like temperature, moisture, and aeration, allowing for accelerated decomposition and efficient odor management. They are commonly used in commercial and municipal composting operations.

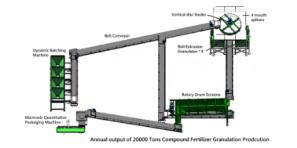

Continuous Composting Systems: Continuous composting systems operate on a continuous feeding and harvesting cycle. Organic waste is continually added to one end of the system, while finished compost is harvested from the other end. These systems provide a continuous supply of compost and are suitable for large-scale composting operations.

Tumbler Composters: Tumbler composters consist of rotating drums or chambers that allow for easy turning and mixing of the compost pile. By tumbling the waste materials, these machines enhance aeration and promote faster decomposition. Tumbler composters are popular among home gardeners and small-scale composting operations.

Applications of Compost Machines:

Home and Backyard Composting: Compost machines cater to the needs of home gardeners and individuals practicing composting at a small scale. They simplify the composting process, making it more accessible and efficient for producing high-quality compost for gardens, lawns, and plants.

Municipal and Commercial Composting: Compost machines are extensively used in larger-scale composting operations, such as municipal composting facilities and commercial composting centers. These machines handle significant volumes of organic waste, allowing for efficient processing and the production of compost for various applications, including landscaping, agriculture, and horticulture.

Food Processing and Agriculture: Compost machines find applications in food processing industries and agricultural settings. They efficiently process food waste, crop residues, and byproducts, converting them into valuable compost. This supports sustainable waste management practices, nutrient recycling, and soil improvement in agricultural operations.

Industrial and Institutional Composting: Compost machines are employed in industrial and institutional settings, including hotels, restaurants, schools, and hospitals. These machines streamline the composting process, enabling efficient management of food waste and organic materials generated in these facilities, reducing waste sent to landfills, and promoting environmental sustainability.

Compost machines simplify the composting process, offering time efficiency, accelerated decomposition, odor and pest control, and space efficiency. In-vessel composters, continuous composting systems, and tumbler composters are among the various types available to cater to different scales and requirements. Compost machines find applications in home composting, municipal and commercial composting, food processing, agriculture, and industrial settings. By incorporating a compost machine into your organic waste management practices, you can produce high-quality compost, reduce waste, and contribute to a more sustainable and environmentally friendly approach to waste disposal and soil enrichment.