Graphite granule granulation equipment

Graphite granule granulation equipment refers to the machinery and equipment used to granulate or pelletize graphite materials into granules of specific sizes and shapes. This equipment is designed to process graphite powders or mixtures with binders and additives to form compact and uniform granules. Some common types of graphite granule granulation equipment include:

1. Granulators: Granulators are commonly used in the granulation process to transform graphite powder into granules. They utilize rotating blades or knives to cut and shape the graphite mixture into desired granule sizes.

2. Fluidized bed granulators: Fluidized bed granulators use a fluidizing air stream to suspend and agitate the graphite powder, allowing it to form granules through the binding action of binders or additives. The granules are then dried and cooled before being collected.

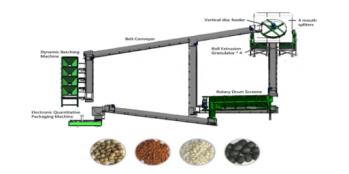

3. Rotary drum granulators: Rotary drum granulators consist of a rotating drum or cylinder where graphite powder is mixed with binders and additives. As the drum rotates, the mixture agglomerates and forms granules due to the rolling and tumbling action.

4. Extrusion granulators: Extrusion granulators involve the extrusion of graphite mixture through a die to form cylindrical or other specific-shaped granules. The mixture is typically heated and forced through the die by a screw or piston mechanism.

5. Spray granulation equipment: Spray granulation equipment utilizes a spraying mechanism to atomize a binder solution or suspension onto the graphite powder, forming granules as the liquid solidifies upon contact.

These types of equipment can vary in terms of size, capacity, automation level, and specific features depending on the requirements of the graphite granulation process. It’s important to select the appropriate equipment based on factors such as desired granule size, production volume, process efficiency, and product quality. https://www.yz-mac.com/roll-extrusion-compound-fertilizer-granulator-product/