Graphite grain pelletizing process

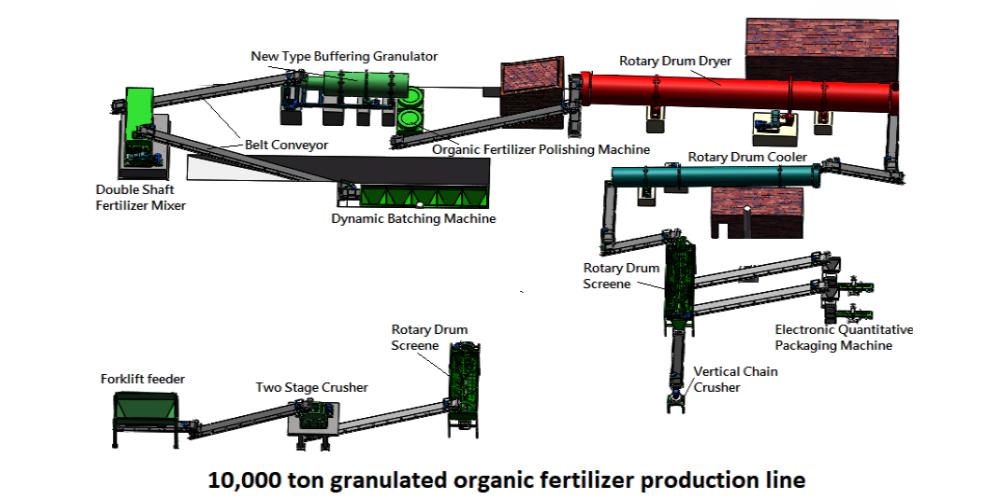

The graphite grain pelletizing process involves transforming graphite grains into compacted and uniform pellets. This process typically includes the following steps:

1. Material Preparation: Graphite grains are obtained either from natural graphite or synthetic graphite sources. The graphite grains may undergo pre-processing steps such as crushing, grinding, and sieving to achieve the desired particle size distribution.

2. Mixing: The graphite grains are mixed with binders or additives, which may include organic binders, inorganic binders, or a combination of both. The binders help to enhance the cohesion and strength of the pellets.

3. Pelletizing: The mixed graphite grains and binders are fed into a pelletizing machine or equipment. The pelletizing machine applies pressure and shaping to the mixture, causing the grains to adhere to each other and form compacted pellets. Various pelletizing techniques can be used, including extrusion, compression, or granulation.

4. Drying: The newly formed graphite pellets are typically dried to remove moisture and solvents from the binders. Drying can be done through methods such as air drying, vacuum drying, or using drying ovens. This step is essential to ensure the pellets have the desired strength and stability.

5. Thermal Treatment: After drying, the graphite pellets may undergo a thermal treatment process, known as calcination or baking. This step involves subjecting the pellets to high temperatures in an inert or controlled atmosphere to remove any remaining binders, enhance their structural integrity, and improve their electrical and thermal conductivity.

6. Cooling and Screening: Once the thermal treatment is complete, the graphite pellets are cooled and then screened to remove any oversized or undersized particles, ensuring uniformity in size and shape.

7. Quality Control: The final graphite pellets may undergo quality control measures, such as testing for density, strength, particle size distribution, and other specific properties required for the intended application.

It’s important to note that the specific details and parameters of the graphite grain pelletizing process may vary depending on the equipment used, the desired pellet properties, and the specific requirements of the application. https://www.yz-mac.com/roll-extrusion-compound-fertilizer-granulator-product/