Cow dung processing machinery

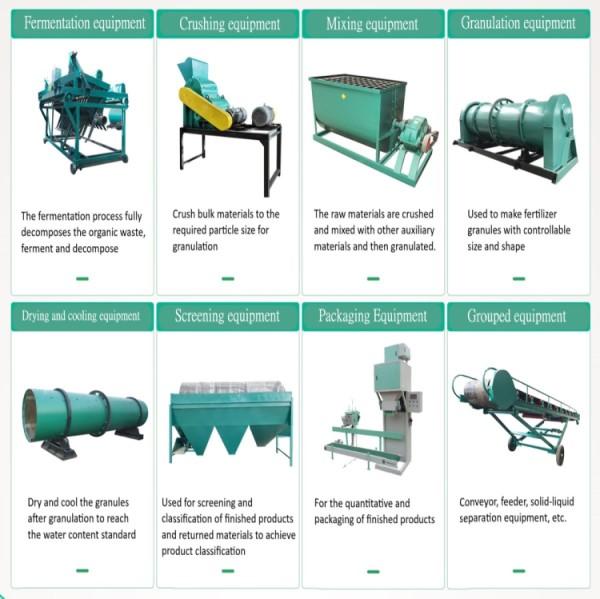

Cow dung, a valuable organic resource, can be effectively processed and utilized using specialized machinery designed for cow dung processing. These machines are capable of converting cow dung into useful products such as compost, biofertilizers, biogas, and briquettes.

The Significance of Cow Dung Processing Machinery:

Cow dung is a rich source of organic matter and nutrients, making it an excellent raw material for various agricultural applications. However, raw cow dung can be challenging to handle and may have limited usability. Cow dung processing machinery plays a vital role in transforming raw cow dung into valuable products, enhancing its agricultural and environmental benefits.

Types of Cow Dung Processing Machinery:

Cow Dung Compost Turners:

Compost turners are designed to efficiently turn and mix cow dung with other organic materials, such as crop residues or green waste, in a composting process. These machines ensure proper aeration, temperature control, and microbial activity, resulting in the rapid decomposition of cow dung and the production of nutrient-rich compost.

Biogas Plants:

Biogas plants utilize anaerobic digestion to convert cow dung into biogas and organic fertilizer. These plants feature specialized digesters that break down cow dung through bacterial fermentation, producing biogas, which can be used for cooking, heating, or generating electricity, and digestate, a nutrient-rich slurry that serves as an organic fertilizer.

Cow Dung Briquette Machines:

Briquette machines compress cow dung into solid fuel briquettes, which can be used as a renewable energy source for cooking and heating. These machines apply pressure and binders to the cow dung, shaping it into compact briquettes that have higher energy density and longer burning time compared to raw cow dung.

Applications of Cow Dung Processing Machinery:

Organic Fertilizer Production:

Cow dung processing machinery, such as compost turners and biogas plants, are essential for the production of organic fertilizers. The processed cow dung is transformed into nutrient-rich compost or digestate, which can be used to improve soil fertility, enhance crop yields, and promote sustainable agriculture practices.

Biogas Generation:

Biogas plants efficiently convert cow dung into biogas, a renewable energy source. The biogas produced can be used for cooking, heating, or generating electricity, reducing reliance on fossil fuels and promoting clean energy alternatives. Additionally, the digestate can be utilized as an organic fertilizer, completing the nutrient cycle.

Sustainable Fuel Source:

Cow dung briquette machines provide a sustainable fuel source by transforming cow dung into solid briquettes. These briquettes serve as a clean-burning alternative to traditional fuels such as firewood or charcoal. They help reduce deforestation and indoor air pollution while utilizing a readily available agricultural waste resource.

Waste Management:

Cow dung processing machinery plays a crucial role in effective waste management. By processing cow dung into valuable products, it reduces the environmental impact of cow dung accumulation, minimizes odor and fly breeding, and prevents the release of harmful methane gas into the atmosphere.

Cow dung processing machinery offers an efficient and sustainable solution for utilizing cow dung as a valuable agricultural waste resource. These machines, including compost turners, biogas plants, and cow dung briquette machines, enable the transformation of raw cow dung into compost, biofertilizers, biogas, and briquettes. Through their applications in organic fertilizer production, biogas generation, sustainable fuel production, and waste management, cow dung processing machinery contributes to sustainable agriculture, renewable energy, and environmental conservation. By harnessing the potential of cow dung, we can maximize its benefits, reduce waste, and promote a greener and more resource-efficient agricultural sector.