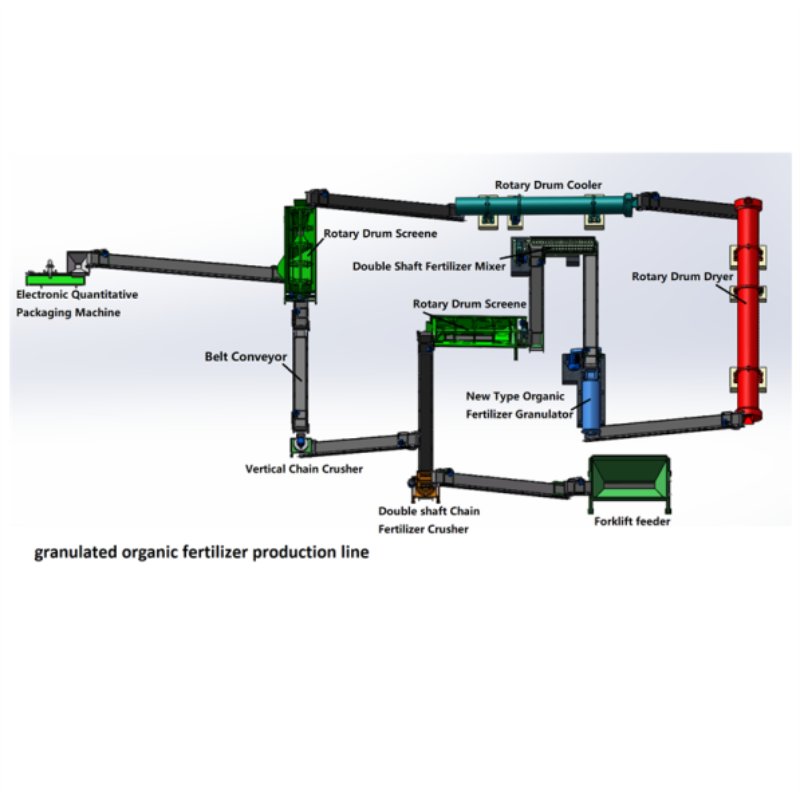

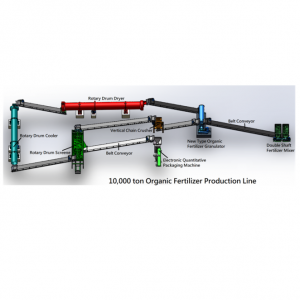

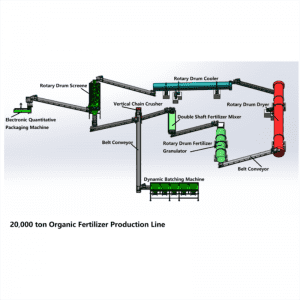

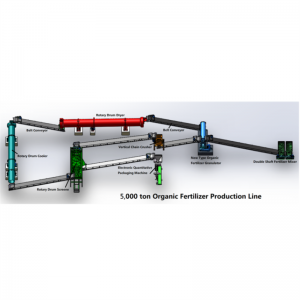

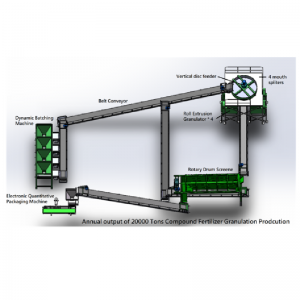

Granular organic fertilizer production line

Granular organic fertilizers are usually used to improve the soil and provide nutrients needed for the growth of crops. When they enter the soil, they can be quickly decomposed and release nutrients quickly. Because solid organic fertilizers are absorbed more slowly, they last longer than powdered organic fertilizers. The use of organic fertilizer greatly reduces the damage to the plant itself and the damage to the soil environment.

Granular organic fertilizer production line is optimized by Yizheng Heavy Industries, a company specializing in the research, development, production and sales of organic fertilizer production equipment. Provide a complete set of fertilizer processing equipment, free installation and commissioning, free training, and maintenance services.

Word Principle:

1. Stir and granulate

During the stirring process, powdery compost is mixed with any desired ingredients or formulas to increase its nutritional value. Then use a new organic fertilizer granulator to make the mixture into particles. Organic fertilizer granulator is used to make dust-free particles of controllable size and shape. The new organic fertilizer granulator adopts a closed process, no respiratory dust discharge, and high productivity.

2. Dry and cool

The drying process is suitable for every plant that produces powdery and granular solid materials. Drying can reduce the moisture content of the resulting organic fertilizer particles, reduce the thermal temperature to 30-40°C, and the granular organic fertilizer production line adopts a roller dryer and a roller cooler.

3. Screening and packaging

After granulation, organic fertilizer particles should be screened to obtain the required particle size and remove particles that do not conform to the particle size of the product. Roller sieve machine is a common sieving equipment, which is mainly used for the classification of finished products and uniform grading of finished products. After sieving, the uniform particle size of organic fertilizer particles is weighed and packaged through an automatic packaging machine transported by a belt conveyor.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/powdered-organic-fertilizer-and-granulated-organic-fertilizer-production-lines/