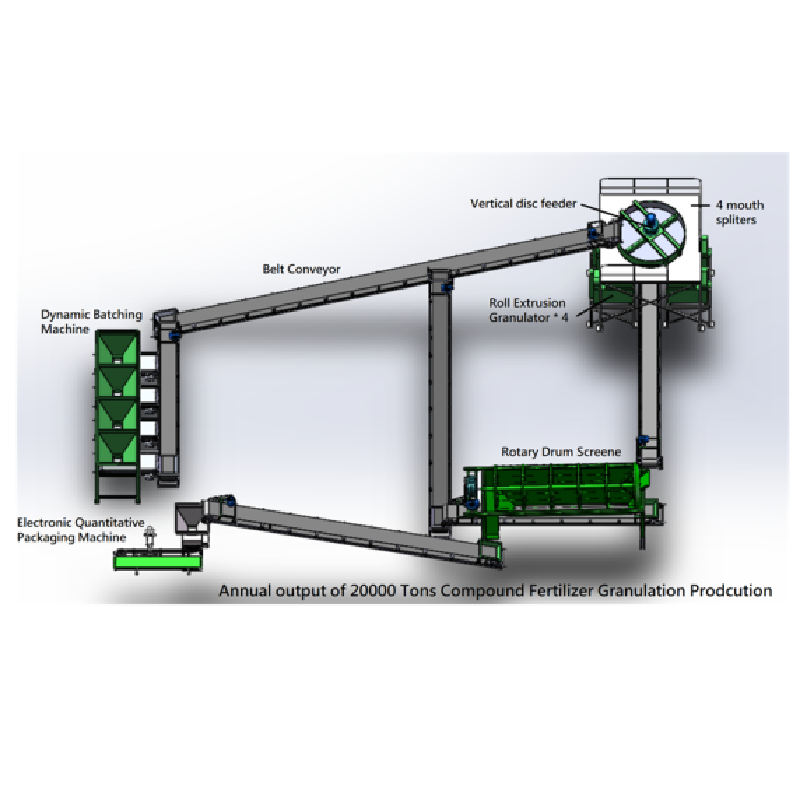

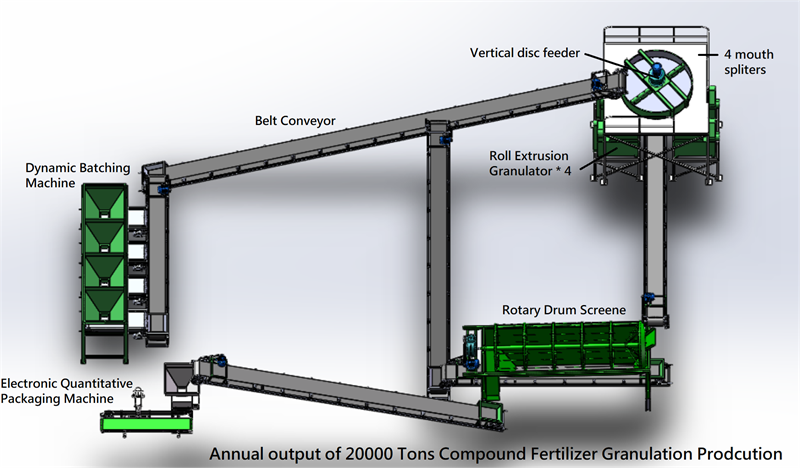

Compound fertilizer production line with an annual output of 20,000 tons.

Compound fertilizer production line with an annual output of 20,000 tons.

With an annual output of 20,000 tons, it can produce high, medium and low concentrated compound fertilizers for various crops. The production line does not require drying, has low investment and low energy consumption.

The pressing rollers of the compound fertilizer production line can be designed into different shapes and sizes so that they can be extruded to produce granules of different sizes and shapes.

The compound fertilizer production line with an annual output of 20,000 tons is optimized by Yizheng Heavy Industry, an enterprise specializing in the research and development, production and sales of organic fertilizer production equipment. Provides a complete set of organic fertilizer production lines for chicken manure, pig manure, cow manure, and sheep manure with an annual output of 10,000 to 200,000 tons. Layout design.

Work Principle :

Generally speaking, the composite fertilizer production line generally consists of the following parts: mixing process, granulation process, crushing process, screening process, coating process and packaging process.

1. Dynamic Batching Machine:

The ingredients of more than three materials can be carried out. The batching machine has more than three silos, and can appropriately increase and reduce the silo according to customer’s requirements. At the exit of each silo, there is a pneumatic electronic door. Under the silo, it is called a hopper, which means that the bottom of the hopper is a belt conveyor. It is said that the hopper and the belt conveyor are hung at one end of the transmission lever, the other end of the lever is connected to the tension sensor, and the sensor and pneumatic control part are connected to the computer. This machine adopts the cumulative weighing of electronic scales, which is automatically controlled by the batching controller, and the weighing ratio of each material is completed in turn. It has the advantages of simple structure, high ingredient accuracy, simple operation and reliable use.

2. Vertical Chain Crusher:

Combine different composite materials in a certain proportion and put them into a vertical chain crusher. The raw materials will be crushed into small particles to meet the needs of the subsequent granulation process.

3. Vertical disc feeder:

After the raw material is crushed, it is sent to the Vertical disc feeder, and the raw material is mixed and stirred evenly in the mixer. The inner lining of the mixer is polypropylene or stainless steel plate. Such raw materials with high corrosion and viscosity are not easy to stick to. The mixed material will enter the drum granulator.

4. Roll Extrusion Granulator:

Adopting dry extrusion technology, the drying process is omitted. It mainly relies on external pressure, so that the material is forced to be compressed into pieces through two reverse roller clearances. The actual density of the material can increase by 1.5-3 times, thus reaching a certain strength standard. Especially suitable for places to increase the product stack weight. The operation elasticity and wide range of adaptation can be adjusted by liquid pressure. The equipment is not only scientific and reasonable in structure, but also has little investment, quick impact and good economic benefits.

5. Rotary Drum Screene:

It is mainly used to separate the finished product from the recycled material. After sieving, qualified particles are fed into the wrapper machine, and unqualified particles are fed into the vertical chain crusher to make granulated again, thus realizing product classification and uniform classification of finished products. The machine adopts a combined screen for easy maintenance and replacement. Its structure is simple and fucked. Convenient and stable operation is an indispensable equipment in fertilizer production.

6. Electronic Quantitative Packaging Machine:

After the particles are screened, they are packaged by the packaging machine. The packaging machine has a high degree of automation, integrating weighing, suture, packaging and transportation, which realizes rapid quantitative packaging and makes the packaging process more efficient and accurate.

7. Belt conveyor:

The conveyor plays an indispensable role in the production process, because it connects different parts of the entire production line. On this compound fertilizer production line, we choose to provide you with a belt conveyor. Compared with other types of conveyors, belt conveyors have large coverage, making your production process more efficient and economical.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/20000-ton-compound-fertilizer-production-linec/